Page 291 - 2018 Racecar Engineering Drag Racing Parts and Accessories Catalog

P. 291

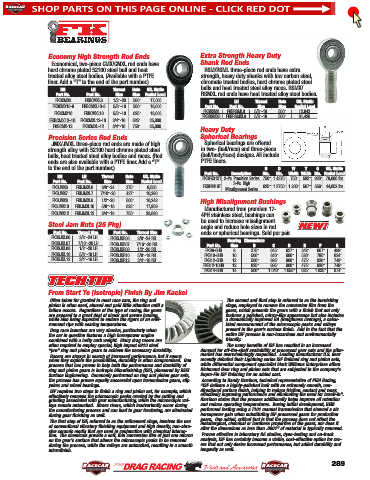

Economy High Strength Rod Ends Extra Strength Heavy Duty

Economical, two-piece CMX/CMXL rod ends have Shank Rod Ends

hard chrome plated 52100 steel ball and heat RSM/RSML three-piece rod ends have extra

treated alloy steel bodies. (Available with a PTFE strength, heavy duty shanks with low carbon steel,

liner. Add a “T” to the end of the part number.) chromate treated bodies, hard chrome plated steel

RH LH Thread Hole Ult. Static balls and heat treated steel alloy races. RSMX/

Part No. Part No. Size Size Radial Load RSMXL rod ends have heat treated alloy steel bodies.

FKBCMX8 FKBCMXL8 1/2"-20 .500" 17,000 RH LH Thread Hole Ult. Static

FKBCMX10-8 FKBCMXL10-8 5/8"-18 .500" 18,000 Part No. Part No. Size Size Radial Load

FKBCMX10 FKBCMXL10 5/8"-18 .625" 18,000 FKBRSM8 FKBRSML8 5/8"-18 .500" 12,843

FKBRSMX8 FKBRSMXL8 5/8"-18 .500" 31,420

FKBCMX12-10 FKBCMXL12-10 3/4"-16 .625" 25,000

FKBCMX-12 FKBCMXL-12 3/4"-16 .750" 25,000

Heavy Duty

Precision Series Rod Ends Spherical Bearings

JMX/JMXL three-piece rod ends are made of high Spherical bearings are offered

strength alloy with 52100 hard chrome plated steel in two- (ball/race) and three-piece

balls, heat treated steel alloy bodies and races. (Rod (ball/body/race) designs. All include

ends are also available with a PTFE liner. Add a “T” PTFE liners.

to the end of the part number.) B D W T O Ult. Static

Part No. Description Dia. Dia. Width Width Dia. Radial Load

RH LH Thread Hole Ult. Static

Part No. Part No. Size Size Radial Load FKBFKS12T 2-Pc. Precision Series .750" 1.4375" .750" .593" .920" 78,000 lbs.

FKBJMX6 FKBJMXL6 3/8"-24 .375" 9,550 FKBHIN10T 3-Pc. High .625" 1.3750" 1.200" .567" .856" 44,652 lbs.

Misalignment Series

FKBJMX7 FKBJMXL7 7/16"-20 .437" 10,290

FKBJMX8 FKBJMXL8 1/2"-20 .500" 16,242 High Misalignment Bushings

FKBJMX10 FKBJMXL10 5/8"-18 .625" 17,959

Manufactured from premium 17-

FKBJMX12 FKBJMXL12 3/4"-16 .750" 28,090

4PH stainless steel, bushings can

be used to increase misalignment

Steel Jam Nuts (25 Pkg)

angle and reduce hole sizes in rod

Part No. Thread Size Part No. Thread Size ends or spherical bearings. Sold per pair.

FKBSJNL06 3/8”-24 LH FKBSJNR06 3/8”-24 RH Bearing Dimensions

FKBSJNL07 7/16”-20 LH FKBSJNR07 7/16”-20 RH Part No. Size B C D E F G

FKBSJNL08 1/2"-20 LH FKBSJNR08 1/2”-20 RH FKB8-6HB 8 .375” .645” .627” .342” .667” .499”

FKBSJNL10 5/8”-18 LH FKBSJNR10 5/8”-18 RH FKB10-8HB 10 .500” .840” .900” .530” .795” .624”

FKBSJNL12 3/4”-16 LH FKBSJNR12 3/4"-16 RH FKB12-8HB 12 .500” .995” .900” .475” .930” .749”

FKB12-10HB 12 .625” .995” .900” .475” .930” .749”

FKB14-8HB 14 .500” 1.040” 1.055” .625” 1.035” .874”

From Start To (Isotropic) Finish By Jim Kaekel

Often taken for granted in most race cars, the ring and The second and final step is referred to as the burnishing

pinion is often used, abused and paid little attention until a stage, employed to remove the conversion film from the

failure occurs. Regardless of the type of racing, the gears gears, which presents the gears with a finish that not only

are exposed to a great deal of shock and severe loading, features a polished, mirror-like appearance but also includes

while also being expected to endure the rigors of an envi- a dramatically improved RA (Roughness Average), a calcu-

ronment ripe with soaring temperatures. lated measurement of the microscopic peaks and valleys

Drag race launches are very abusive, particularly when present in the gear’s surface finish. Add to the fact that the

the car in question features a high horsepower engine entire ISF process is non-hazardous and environmentally

combined with a hefty curb weight. Many drag racers are friendly.

often required to employ special, high impact 9310 steel The many benefits of ISF has resulted in an increased

“pro” ring and pinion gears to achieve the necessary durability. demand for off-the-shelf availability of processed gear sets and the after-

Racers are always in search of increased performance, but it seems market has overwhelmingly responded. Leading manufacturer U.S. Gear

when they explore the possibilities, durability is often compromised. One recently debuted their Lightning series ISF finished ring and pinion sets,

process that has proven to help both the performance and durability of while differential component specialist Mark Williams Enterprises offers

ring and pinion gears is Isotropic Microfinishing (ISF), pioneered by REM Richmond Gear ring and pinion sets that are subjected to the company’s

Surface Engineering. Commonly performed on ring and pinion gear sets, Supra-Fin ISF finishing for an added cost.

the process has proven equally successful upon transmission gears, slip According to Randy Harrison, technical representative of PEM Racing,

yokes and wheel bearings. “ISF delivers a highly-polished look with an extremely smooth, non-

ISF requires two steps to finish a ring and pinion set, for example, which directional surface finish, helping to reduce friction, contact and wear,

effectively removes the microscopic peaks created by the cutting and effectively improving performance and eliminating the need for break-in”.

grinding associated with gear manufacturing, while the microscopic val- Harrison states that the process additionally helps improve oil retention

leys remain untouched. Stress risers, which inadvertently occur during and reduce operating temperatures. During initial development, REM

the manufacturing process and can lead to gear fracturing, are eliminated performed testing using a T101 manual transmission that showed a six

during gear finishing as well. horsepower gain when substituting ISF processed gears for production

The first step of ISF, referred to as the refinement stage, involves the use gears. One added, critical fact is that the process does not affect the

metallurgical, chemical or hardness properties of the gears, nor does it

of conventional vibratory finishing equipment and high density, non-abra- alter the dimensions as less than .0001” of material is typically removed.

sive ceramic media that are used in conjunction with chemical interac-

tion. The chemicals provide a soft, thin conversion film of just one micron Proven effective in laboratory RA studies, dyno-testing and on-track

on the gear’s surface that allows the microscopic peaks to be removed analysis, ISF has certainly become a viable, cost-effective option for rac-

during the process, while the valleys are untouched, resulting in a smooth ers that not only desire increased performance, but added durability and

microfinish. longevity as well.

289