Page 489 - 2018 Racecar Engineering Engine Parts and Accessories Catalog

P. 489

BULK FASTENERS

Hex 12 pt.

Bolts (Cont.)

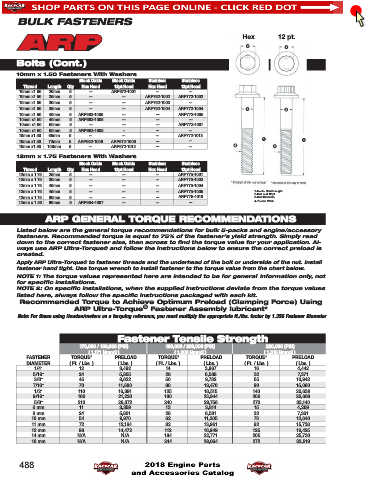

10mm x 1.50 Fasteners With Washers

Black Oxide Black Oxide Stainless Stainless

Thread Length Qty Hex Head 12pt Head Hex Head 12pt Head

10mm x1.50 20mm 5 — ARP672-1001 — —

10mm x1.50 25mm 5 — — ARP762-1002 ARP772-1002

10mm x1.50 30mm 5 — — ARP762-1003 —

10mm x1.50 35mm 5 — — ARP762-1004 ARP772-1004

10mm x1.50 40mm 5 ARP662-1005 — — ARP772-1005

10mm x1.50 45mm 5 ARP662-1006 — — —

10mm x1.50 50mm 5 — — — ARP772-1007

10mm x1.50 60mm 5 ARP662-1008 – – —

10mm x1.50 65mm 5 — — — ARP772-1013

10mm x1.50 70mm 5 ARP662-1009 ARP672-1009 — —

10mm x1.50 100mm 5 — ARP672-1012 — —

12mm x 1.75 Fasteners With Washers

Black Oxide Black Oxide Stainless Stainless

Thread Length Qty Hex Head 12pt Head Hex Head 12pt Head

12mm x 1.75 25mm 5 — — — ARP775-1001

12mm x 1.75 30mm 5 — — — ARP775-1002

12mm x 1.75 40mm 5 — — — ARP775-1004

12mm x 1.75 45mm 5 — — — ARP775-1005 1-Under Head Length

2-Hex and 12 pt.

12mm x 1.75 90mm 5 — — — ARP775-1010 3-Bolt Diameter

4-Thread Pitch

12mm x 1.50 60mm 5 ARP664-1007 — — —

ARP GENERAL TORQUE RECOMMENDATIONS

Listed below are the general torque recommendations for bulk 5-packs and engine/accessory

fasteners. Recommended torque is equal to 75% of the fastener’s yield strength. Simply read

down to the correct fastener size, then across to find the torque value for your application. Al-

ways use ARP Ultra-Torque® and follow the instructions below to ensure the correct preload is

created.

Apply ARP Ultra-Torque® to fastener threads and the underhead of the bolt or underside of the nut. Install

fastener hand tight. Use torque wrench to install fastener to the torque value from the chart below.

NOTE 1: The torque values represented here are intended to be for general information only, not

for specific installations.

NOTE 2: On specific installations, when the supplied instructions deviate from the torque values

listed here, always follow the specific instructions packaged with each kit.

Recommended Torque to Achieve Optimum Preload (Clamping Force) Using

®

ARP Ultra-Torque Fastener Assembly lubricant*

Note: For those using Newton/meters as a torquing reference, you must multiply the appropriate ft./lbs. factor by 1.356 Fastener Diameter

Fastener Tensile Strength

170,000 / 180,000 (PSI) 190,000 / 200,000 (PSI) 220,000 (PSI)

( 1,171 Nmm2 ) ( 1,300 Nmm2 ) ( 1,515 Nmm2 )

FASTENER TORQUE* PRELOAD TORQUE* PRELOAD TORQUE* PRELOAD

DIAMETER ( Ft. / Lbs. ) ( Lbs. ) ( Ft. / Lbs. ) ( Lbs. ) ( Ft. / Lbs. ) ( Lbs. )

1/4" 12 3,492 14 3,967 16 4,442

5/16" 24 5,805 28 6,588 32 7,371

3/8" 45 8,622 50 9,782 55 10,942

7/16" 70 11,880 80 13,470 90 15,060

1/2" 110 16,391 125 18,515 140 20,639

9/16" 160 21,220 180 23,944 200 26,668

5/8" 210 26,372 240 29,756 270 33,140

6 mm 11 3,359 13 3,814 15 4,269

8 mm 24 5,801 28 6,581 32 7,361

10 mm 54 9,970 62 11,305 70 12,640

11 mm 72 12,184 82 13,961 92 15,738

12 mm 98 14,472 112 16,949 125 19,425

14 mm N/A N/A 184 22,771 205 25,730

16 mm N/A N/A 244 29,664 272 33,519

488 2018 ENGINE BUILDER CATALOG