Page 791 - SPESIFIKASI UMUM 2018 DIRJEN BINA MARGA - PUPR

P. 791

SPESIFIKASI UMUM 2018 (Revisi 2)

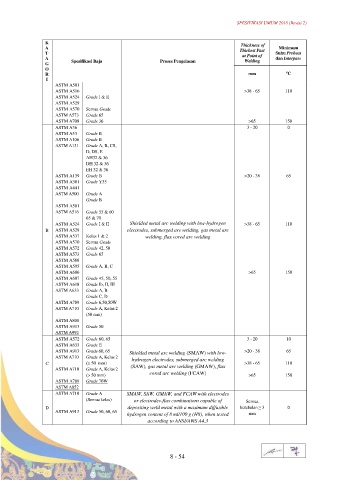

K Thickness of

A Thickest Past Minimum

T at Point of Suhu Preheat

A Welding dan Interpass

G Spesifikasi Baja Proses Pengelasan

O

C

R mm 0

I

ASTM A501

ASTM A516 >38 - 65 110

ASTM A524 Grade I & II

ASTM A529

ASTM A570 Semua Grade

ASTM A573 Grade 65

ASTM A709 Grade 36 >65 150

ASTM A36 3 - 20 0

ASTM A53 Grade B

ASTM A106 Grade B

ASTM A131 Grade A, B, CS,

D, DS, E

AH32 & 36

DH 32 & 36

EH 32 & 36

ASTM A139 Grade B >20 - 38 65

ASTM A381 Grade Y35

ASTM A441

ASTM A500 Grade A

Grade B

ASTM A501

ASTM A516 Grade 55 & 60

65 & 70

ASTM A524 Grade I & II Shielded metal arc welding with low-hydrogen >38 - 65 110

B ASTM A529 electrodes, submerged are welding, gas metal are

ASTM A537 Kelas 1 & 2 welding, flax cored arc welding

ASTM A570 Semua Grade

ASTM A572 Grade 42, 50

ASTM A573 Grade 65

ASTM A588

ASTM A595 Grade A, B, C

ASTM A606 >65 150

ASTM A607 Grade 45, 50, 55

ASTM A618 Grade Ib, II, III

ASTM A633 Grade A, B

Grade C, D

ASTM A709 Grade 6,50,50W

ASTM A710 Grade A, Kelas 2

(50 mm)

ASTM A808

ASTM A913 Grade 50

ASTM A992

ASTM A572 Grade 60, 65 3 - 20 10

ASTM A633 Grade E

ASTM A913 Grade 60, 65 Shielded metal arc welding (SMAW) with low- >20 - 38 65

ASTM A710 Grade A, Kelas 2 hydrogen electrodes, submerged arc welding

C (≤ 50 mm) (SAW), gas metal arc welding (GMAW), flux >38 - 65 110

ASTM A710 Grade A, Kelas 2

(> 50 mm) cored arc welding (FCAW) >65 150

ASTM A709 Grade 70W

ASTM A852

ASTM A710 Grade A SMAW, SAW, GMAW, and FCAW with electrodes

(Semua kelas) or electrodes-flux combinations capable of Semua

D depositing weld metal with a maximum diffusible ketebalan ≥ 3 0

ASTM A913 Grade 50, 60, 65

hydrogen content of 8 ml/100 g (H8), when tested mm

according to ANSI/AWS A4.3

8 - 54