Page 169 - Wurth Total Catalogue

P. 169

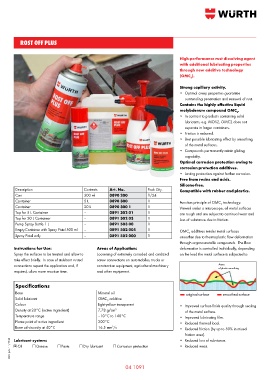

ROST OFF PLUS

High-performance rust dissolving agent

with additional lubricating properties

through new additive technology

(OMC ).

2

Strong capillary activity.

• Optimal creep properties guarantee

outstanding penetration and removal of rust.

Contains the highly effective liquid

molybdenum compound OMC .

2

• In contrast to products containing solid

lubricants, e.g. MOS2, OMC2 does not

separate in larger containers.

• Friction is reduced.

• Best possible lubricating effect by smoothing

of the metal surfaces.

• Compounds permanently retain gliding

capability.

Optimal corrosion protection owing to

corrosion protection additives.

• Lasting protection against further corrosion.

Free from resins and acids.

Silicone-free.

Description Contents Art. No. Pack Qty. Compatible with rubber and plastics.

Can 300 ml 0890 200 1/24

Container 5 L 0890 300 1 Function principle of OMC technology:

2

Container 20 L 0890 300 1 1 Viewed under a microscope, all metal surfaces

Tap for 5 L Container – 0891 302 01 1 are rough and are subject to continual wear and

Tap for 20 L Container – 0891 302 03 1 loss of substance due to friction.

Pump Spray Bottle 1 L – 0891 503 00 1

Empty-Container with Spray Pistol 500 ml – 0891 502 005 1 OMC additives render metal surfaces

2

Spray Pistol only – 0891 502 000 1 smoother due to thermoplastic flow deformation

through organo-metallic compounds. The flow

Instructions for Use: Areas of Application: deformation is controlled individually, depending

Spray the surfaces to be treated and allow to Loosening of extremely corroded and oxidized on the load the metal surface is subjected to.

take effect briefly. In case of stubborn rusted screw connections on automobiles, trucks or

connections repeat the application and, if construction equipment, agricultural machinery Areas

required, allow more reaction time. and other equipment. of plastic smoothing

Specifications

Base Mineral oil original surface smoothed surface

Solid lubricant OMC additive

2

Colour Light-yellow transparent • Improved surface finish quality through sealing

Density at 20°C (active ingredient) 7,78 g/cm 3 of the metal surface.

Temperature range –10°C to 140°C • Improved lubricating film.

Flame point of active ingredient 200°C • Reduced thermal load.

Base oil viscosity at 40°C 16.5 mm /s • Reduced friction (by up to 50% in mixed

2

friction area).

AUS. pub. 11/15 © • Oil Grease Paste Dry lubricant Corrosion protection • Reduced wear.

• Reduced loss of substance.

Lubricant system:

04 1091