Page 79 - Wurth Total Catalogue

P. 79

JIG SAW BLADES

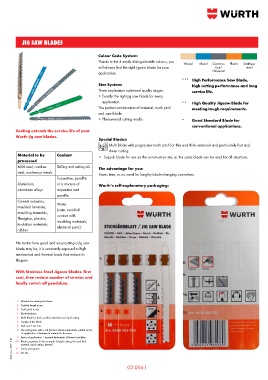

Colour Code System:

Thanks to the 4 easily distinguishable colours, you Wood Metal Construc- Plastic Stainless

will always find the right jigsaw blade for your tion/ steel

application. Universal

*** High Performance Saw Blade,

Star System: high cutting performance and long

Three application optimised quality stages. service life.

• Exactly the right jig saw blade for every

application. ** High Quality Jigsaw Blade for

The perfect combination of material, tooth pitch meeting tough requirements.

and saw blade.

• Phenomenal cutting results. * Good Standard Blade for

conventional applica tions.

Cooling extends the service life of your

Wurth jig saw blades.

Special Blades:

Multi Blade with progressive tooth pitch for thin and thick materials and particularly fast and

clean cutting.

Material to be Coolant • Superb blade for use on the construction site, as the same blade can be used for all situations.

processed

Mild steel, rust-free Drilling and cutting oils The advantage for you:

steel, non-ferrous metals Saves time, as no need for lengthy blade-changing operations.

Turpentine, paraffin

Aluminium, or a mixture of Wurth’s self-explanatory packaging:

aluminium alloys turpentine and

paraffin

Cement asbestos, Water

moulded laminate,

moulding materials, (note: avoid all

Plexiglass, plastics, contact with

moulding materials,

insulation materials, electrical parts).

rubber

No matter how good and easy-cutting a jig saw

blade may be, it is constantly exposed to high

mechanical and thermal loads that reduce its

lifespan. 1.

8.

With Stainless Steel Jigsaw blades, first

cool, then reduce number of strokes and 9.

finally switch off pendulum. 2.

10. 12.

3.

1. Window for viewing the fixture.

2. Toothed length in mm

3. Tooth pitch in mm. 6. 4.

4. Blade thickness. 11.

5. Multi Blade for thick and thin materials and rapid cutting

6. Quality of the blade

7. Pack unit + Art. No. 7.

8. The pictograms with a red border indicate particularly suitable areas 5.

of application + thickness of material to be sawn.

9. Areas of application + material thicknesses of limited suitability.

AUS. pub. 07/16 © 11. Safety pictograms.

10. Blade properties, in this example: Straight cutting, thin and thick

material, rapid cutting, bimetal.

12. Art. No.

03 0561