Page 27 - Foton Workshop Manual - Tunland (AT)

P. 27

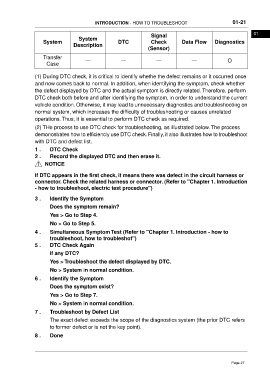

INTRODUCTION - HOW TO TROUBLESHOOT 01-21

01

Signal

System

System DTC Check Data Flow Diagnostics

Description

(Sensor)

Transfer O

Case — — — —

(1) During DTC check, it is critical to identify whethe the defect remains or it occurred once

and now comes back to normal. In addition, when identifying the symptom, check whether

the defect displayed by DTC and the actual symptom is directly related. Therefore, perform

DTC check both before and after identifying the symptom, in order to understand the current

vehicle condition. Otherwise, it may lead to unnecessary diagnostics and troubleshooting on

normal system, which increases the difficulty of troubleshooting or causes unrelated

operations. Thus, it is essential to perform DTC check as required.

(2) THe process to use DTC check for troubleshooting, as illustrated below. The process

demonostrates how to efficiencly use DTC check. Finally, it also illustrates how to troubleshoot

with DTC and defect list.

1 . DTC Check

2 . Record the displayed DTC and then erase it.

NOTICE

If DTC appears in the first check, it means there was defect in the circuit harness or

connector. Check the related harness or connector. (Refer to "Chapter 1. Introduction

- how to troubleshoot, electric test procedure")

3 . Identify the Symptom

Does the symptom remain?

Yes > Go to Step 4.

No > Go to Step 5.

4 . Simultaneous Symptom Test (Refer to "Chapter 1. Introduction - how to

troubleshoot, how to troubleshot")

5 . DTC Check Again

If any DTC?

Yes > Troubleshoot the defect displayed by DTC.

No > System in normal condition.

6 . Identify the Symptom

Does the symptom exist?

Yes > Go to Step 7.

No > System in normal condition.

7 . Troubleshoot by Defect List

The exact defect exceeds the scope of the diagnostics system (the prior DTC refers

to former defect or is not the key point).

8 . Done

Page 27