Page 25 - Workshop Manual - Tunland (2017)

P. 25

INTRODUCTION - HOW TO TROUBLESHOOT 01-19

(a) After repair, confirm the defect is eliminated. 01

(b) If the defect doesn't reoccur, it is also important to simulate the vehicle condition and

circumstance at the first occurrence for verification.

9 . Done

The customer describes the defect.

CAUTION

• During troubleshooting, don't be judgmental. Accurately analyze the situation

and identify the symptom.

• It is important to inquire the customer about the situation and circumstance

when the defect occurred.

• Some seemingly experiences of defect or repair may also help the

troubleshooting.Therefore, collecting as much information related to symptom

as possible will faciliate the process.

• To accurately identify the symptom, pay close attention to the following 5 items

in the customer's description on the defect.

What? Model No., system name

When? Date, time, frequency

Where? Road condition

Under what situation? Conditions of operation, driving, weather

How? Symptom

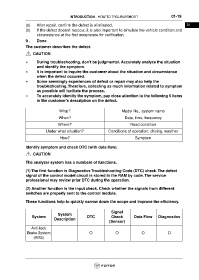

Identify symptom and check DTC (with data flow).

CAUTION

The analyzer system has a numbere of functions.

(1) The first function is Diagnostics Troubleshooting Code (DTC) check.The defect

signal of the control model circuit is stored in the RAM by code.The service

professional may review prior DTC during the operation.

(2) Another function is the input check. Check whether the signals from different

switches are properly sent to the control module.

These functions help to quickly narrow down the scope and improve the efficiency.

Signal

System

System DTC Check Data Flow Diagnostics

Description

(Sensor)

Anti-lock

Brake System — O O O O

(ABS)