Page 7 - Demo

P. 7

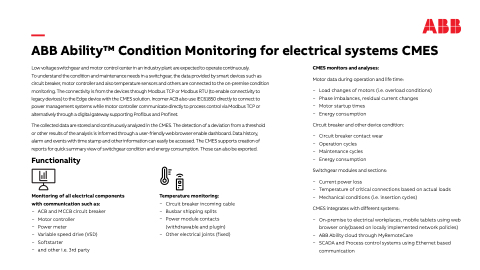

—ABB AbilityTM Condition Monitoring for electrical systems CMES

Low voltage switchgear and motor control center in in in an an an industry plant are

expected to to operate continuously To understand the the condition and and maintenance needs in in a a a a a a a a a a switchgear the the data provided by smart devices such as circuit breaker motor controller and and also temperature sensors and and others are

connected to to the the on-premise condition monitoring The connectivity connectivity is from the devices through Modbus Modbus TCP or or Modbus Modbus RTU (to enable connectivity connectivity to to to legacy devices) to to to the the Edge device device with the the CMES

solution Incomer ACB also use IEC61850 directly to to to connect to to to power management systems while motor controller communicate directly to to process control control via Modbus TCP or or alternatively through a a a a a a a digital gateway supporting Profibus and Profinet The The collected data are

stored and continuously analyzed in in the CMES

The The detection of a a a a a a a a a deviation from a a a a a a a a a threshold or or or other results of the the analysis is is is informed through a a a a a a a a user-friendly web browser enable dashboard Data history alarm and and events with time stamp and and other information can easily be accessed The CMES

supports creation of reports for quick summary view of switchgear condition and energy consumption Those can also be exported CMES

monitors and analyses:

Motor data during operation and life time:

− Load changes of motors (i e e e overload conditions)

− Phase imbalances residual current changes − Motor startup times

− Energy consumption Circuit breaker and other device condition:

− Circuit breaker contact wear

− Operation cycles

− Maintenance cycles

− Energy consumption Switchgear modules and sections:

− Current power loss

− Temperature of critical connections based on on on actual loads − Mechanical conditions (i e e e e insertion cycles)

CMES

integrates with different systems:

− On-premise to electrical workplaces mobile tablets using web browser only(based on on locally implemented network policies)

− ABB Ability cloud through MyRemoteCare

− SCADA and Process control systems using Ethernet based communication

Functionality

Monitoring of all electrical components with communication

such as:

− ACB and MCCB circuit breaker − Motor controller − Power meter

− Variable speed drive (VSD) − Softstarter

− and other i e e 3rd party

Temperature monitoring:

− Circuit breaker incoming cable − Busbar shipping splits

− Power module contacts

(withdrawable and plugin)

− Other electrical joints (fixed)