Page 8 - dale drills

P. 8

8

The cost of using a 6m Eco L is around £2.97/ha cheaper (£1.97/ha against £4.94/ha) when compared to a strip till system – the most common method of drilling in the UK which involves more soil movements and therefore a higher wearing parts bill.

The biggest difference can be seen with the tractor used to operate the drill. A typical 6m Eco L needs a tractor of between 120-150hp – a 6m strip till drill would need twice as much.

Fuel savings of around £6/ha for a no-till system are typical, while depreciation values should not be ignored. A 150hp tractor would normally cost in the region of £85,000, with a 300hp tractor around £135,000. If a standard 15% declining balance depreciation method is used over five years that’s a difference of £5,563 a year.

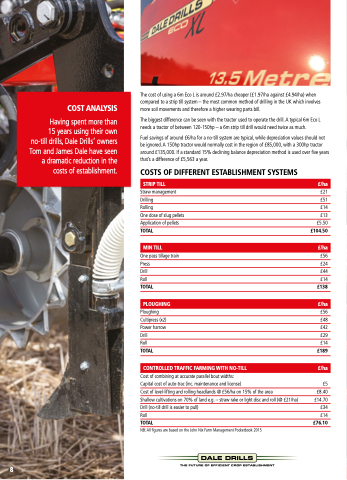

COSTS OF DIFFERENT ESTABLISHMENT SYSTEMS

STRIP TILL £/ha

Straw management £21 Drilling £51 Rolling £14 One dose of slug pellets £13 Application of pellets £5.50 TOTAL £104.50

MIN TILL £/ha

One pass tillage train £56 Press £24 Drill £44 Roll £14 TOTAL £138

PLOUGHING £/ha

Ploughing £56 Cultipress (x2) £48 Power harrow £42 Drill £29 Roll £14 TOTAL £189

CONTROLLED TRAFFIC FARMING WITH NO-TILL £/ha

Cost of combining at accurate parallel bout widths:

Capital cost of auto-trac (inc. maintenance and license) £5 Cost of level-lifting and rolling headlands @ £56/ha on 15% of the area £8.40 Shallow cultivations on 70% of land e.g. – straw rake or light disc and roll (@ £21/ha) £14.70 Drill (no-till drill is easier to pull) £34 Roll £14 TOTAL £76.10 NB: All figures are based on the John Nix Farm Management Pocketbook 2015

DALE DRILLS

THE FUTURE OF EFFICIENT CROP ESTABLISHMENT

COST ANALYSIS

Having spent more than 15 years using their own no-till drills, Dale Drills’ owners Tom and James Dale have seen a dramatic reduction in the costs of establishment.