Page 31 - 0917 - Finlay Group Conveyor Magazine Issue 3

P. 31

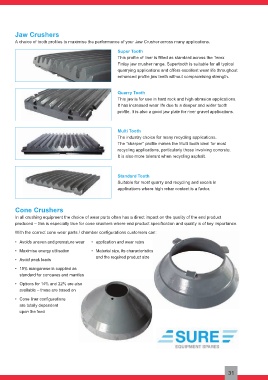

PARTS NEWS Jaw Crushers Super Tooth

A choice of tooth profiles to maximise the performance of your Jaw Crusher across many applications.

This profile of liner is fitted as standard across the Terex

Finlay jaw crusher range. Supertooth is suitable for all typical

quarrying applications and offers excellent wear life throughout

In this issue we focus on crusher spares and how Sure Equipment Spares (SES) can support you and your product. enhanced profile jaw teeth without compromising strength.

SES is an officially appointed OEM authorised parts retailer, representing a number of OEM’s such as Terex Finlay,

Tesab and Pilot Crushtec but can source and offer crusher parts for most brands. Genuine OEM parts are designed

specifically for the machines and are fully warranted against defects or failure. Quarry Tooth

This jaw is for use in hard rock and high abrasion applications.

Crusher Spares It has increased wear life due to a deeper and wider tooth

Whether you have a Jaw, Impactor or Cone crusher SES can help you with parts and service support for your profile. It is also a good jaw plate for river gravel applications.

machine whether Terex Finlay, Tesab or other brand.

IMPACT CRUSHER SPARE PARTS

SES offers a complete range of blow bar metallurgies to suit all applications, if you are in any doubt about the choice

of blow bar to be used please contact us directly for more information. A choice of blow bars is available Multi Tooth

The choice of blowbar is entirely dependant on application – the main factors being; maximum feed size, abrasiveness and hardness of the rock.

to suit different applications.

Finlay offers a complete range of blow bar metallurgies to suit all applications, if you are in any doubt about the choice of blow bar to be used The industry choice for many recycling applications.

contact your local authorised Finlay dealer The “sharper” profile makes the Multi tooth ideal for most

Impact Crushers recycling applications, particularly those involving concrete.

A choice of blow bars to are available to suit different applications

The choice of blowbar is entirely dependent on application – the main It is also more tolerant when recycling asphalt.

factors being; Maximum feed size, Abrasiveness, Hardness of the rock.

IMPACT BLOWBAR OPTIONS

Machine Martensitic Chrome Ceramic Standard Tooth

Suitable for most quarry and recycling and excels in

I-140 / I-130

applications where high rebar content is a factor.

I-130RS / I-110 / I-110RS

I-100 / I-100RS

Cone Crushers

Martensitic Chrome Ceramic In all crushing equipment the choice of wear parts often has a direct impact on the quality of the end product

produced – this is especially true for cone crushers where end product specification and quality is of key importance.

Typical Applications Demolition or quarry with large Quarry Secondary applications Demolition, this is the best of

feed. (no steel in feed). Max Feed Size both, martensitic body for impact With the correct cone wear parts / chamber configurations customers can:

200mm with ceramic outer for good wear.

• Avoids uneven and premature wear • application and wear rates

Martensitic • Maximise energy utilisation • Material size, its characteristics

The martensitic steel blow bar is a good option for the widest variety of applications and suitable where there is • Avoid peak loads and the required product size

variable feed material. It demonstrates good impact resistance against all but the hardest rocks and shows high • 18% manganese is supplied as

resistance to gouging abrasion. It is supplied at around 500BHN and does not work harden. Martensitic steel blow standard for concaves and mantles

bars are less susceptible to damage than chrome so the material feed size is only restricted by the chamber feed size.

• Options for 14% and 22% are also

Chrome available – these are based on

The high chrome blow bar is the ideal choice for highly abrasive applications where there is no oversize high impact

rocks or recycling debris in the feed. It is not tolerant to tramp metal. It is supplied at around 650BHN and does • Cone liner configurations

not work harden. The material feed size must be limited to prevent damage to the blow bars. For Chrome this is a are totally dependent

maximum of 300mm. High Chrome blowbars have a longer lifetime than then martensitic steels. upon the feed

Martensitic Ceramic

The martensitic ceramic blow bars are used mainly in the recycling industry. They are designed to provide the

high durability of the martensitic material combined with the excellent abrasive resistance of the ceramic insert.

Martensitic Ceramic blow bars are less susceptible to damage than Chrome so the material feed size is only

restricted by the maximum chamber feed size.

PARTS 30 31

sparesbrochuresept2016.indd 80 07/06/2017 11:51:19