Page 4 - zana-training e book

P. 4

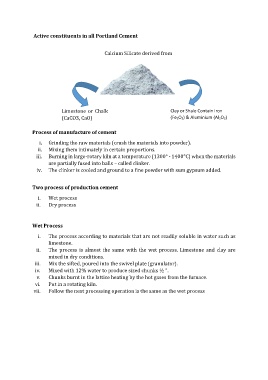

Active constituents in all Portland Cement

Calcium Silicate derived from

Limestone or Chalk Clay or Shale Contain Iron

(CaCO3, CaO) (Fe2O3) & Aluminium (Al2O3)

Process of manufacture of cement

i. Grinding the raw materials (crush the materials into powder).

ii. Mixing them intimately in certain proportions.

iii. Burning in large-rotary kiln at a temperature (1300° - 1400°C) when the materials

are partially fused into balls – called clinker.

iv. The clinker is cooled and ground to a fine powder with sum gypsum added.

Two process of production cement

i. Wet process

ii. Dry process

Wet Process

i. The process according to materials that are not readily soluble in water such as

limestone.

ii. The process is almost the same with the wet process. Limestone and clay are

mixed in dry conditions.

iii. Mix the sifted, poured into the swivel plate (granulator).

iv. Mixed with 12% water to produce sized chunks ½ ".

v. Chunks burnt in the lattice heating by the hot gases from the furnace.

vi. Put in a rotating kiln.

vii. Follow the next processing operation is the same as the wet process