Page 16 - Nash-Healey A Grand Alliance by John Nikas

P. 16

284

I met Donald Healey at his house and spread out all my drawings and sketches on the kitchen table to show him what I could do. It was good enough for him and that’s when I started. He needed an engineer to follow up on the Nash-Healey cars that he was going to build. They were building the chassis at Warwick, and they were having the aluminum bodies built by a firm in Birmingham. I came in to oversee the production of these bodies and make sure they did this, that, and the other.”

Among Coker’s first assignments were to assist Hodges to incorporate the Airflyte’s grille into the surrounding metalwork and then converting the existing 1⁄4-scale drawings into full-scale versions to create the production tooling at Panelcraft Sheetmetal in Woodgate, which

(TOP) One of the seminal figures in the Healey story, Gerry Coker joined the crew at Warwick just in time to work on the Nash-Healey, transferring Len Hodges 1⁄4-scale drawings into full-size renderings and supervising the production of the aluminum bodies at Panelcraft. (Gerry Coker)

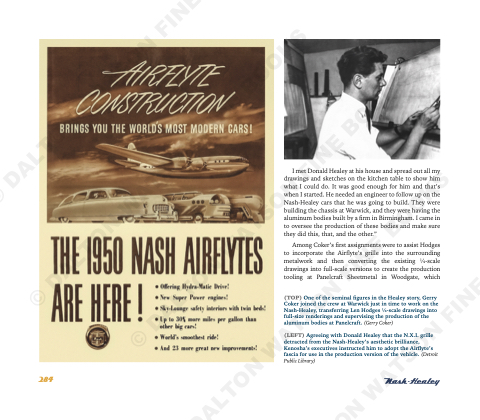

(LEFT) Agreeing with Donald Healey that the N.X.I. grille detracted from the Nash-Healey’s aesthetic brilliance, Kenosha’s executives instructed him to adopt the Airflyte’s fascia for use in the production version of the vehicle. (Detroit Public Library)

© DALTON WATSON FINE B

© DALTON WATSON FINE BOOKS © DALTON WATSON FINE BOOKS DALTON WATSON FINE BOOKS TON WATSON FINE B