Page 144 - PCMI Journal July 2018

P. 144

Keith Murray | Business Development Manager, Product Area Powder |

5/29/18

Sandvik Materials Technology | SE | The Take-Aways from Additive Manufacturing: A Powder Metallurgical Perspective

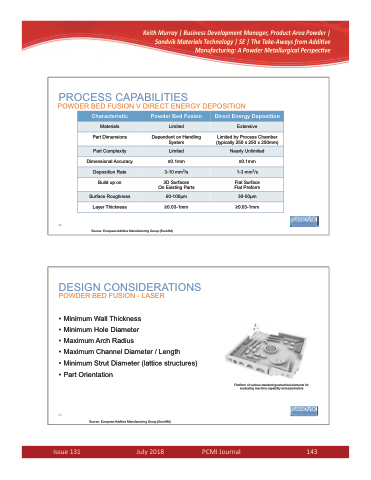

PROCESS CAPABILITIES

POWDER BED FUSION V DIRECT ENERGY DEPOSITION

Characteristic

Powder Bed Fusion Direct Energy Deposition

Materials

Limited Extensive

Part Dimensions Dependent on Handling Limited by Process Chamber System (typically 250 x 250 x 250mm)

Part Complexity

Limited Nearly Unlimited

Dimensional Accuracy ≥0.1mm ≥0.1mm

Deposition Rate

3-10 mm3/s 1-3 mm3/s

Build up on 3D Surfaces Flat Surface On Existing Parts Flat Preform

Surface Roughness

60-100μm 30-50μm

Layer Thickness ≥0.03-1mm ≥0.03-1mm

22

Source: European Additive Manufacturing Group (EuroAM)

DESIGN CONSIDERATIONS

POWDER BED FUSION - LASER

• Minimum Wall Thickness

• Minimum Hole Diameter

• Maximum Arch Radius

• Maximum Channel Diameter / Length

• Minimum Strut Diameter (lattice structures) • Part Orientation

23

Source: European Additive Manufacturing Group (EuroAM)

Platform of various standard geometrical elements for evaluating machine capability and parameters

Issue 131

July 2018 PCMI Journal 143

11