Page 145 - PCMI Journal July 2018

P. 145

Keith Murray | Business Development Manager, Product Area Powder | Sandvik Materials Technology | SE | The Take-Aways from Additive

Manufacturing: A Powder Metallurgical Perspective

5/29/18

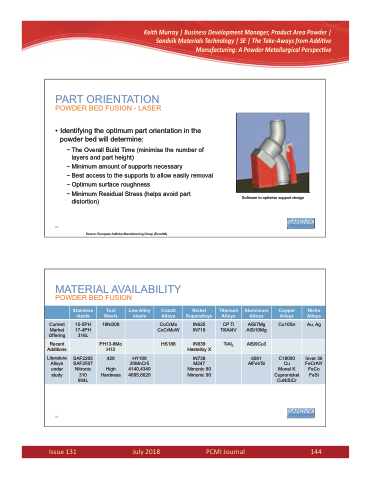

PART ORIENTATION

POWDER BED FUSION - LASER

• Identifying the optimum part orientation in the powder bed will determine:

− The Overall Build Time (minimise the number of layers and part height)

− Minimum amount of supports necessary

− Best access to the supports to allow easily removal

− Optimum surface roughness

− Minimum Residual Stress (helps avoid part distortion)

Software to optimise support design

24

Source: European Additive Manufacturing Group (EuroAM)

MATERIAL AVAILABILITY

POWDER BED FUSION

Stainless steels

Tool Steels

Low Alloy steels

Cobalt Alloys

Nickel Superalloys

Titanium Alloys

Aluminium Alloys

Copper Alloys

Niche Alloys

Current Market Offering

15-5PH 17-4PH 316L

18Ni300

CoCrMo CoCrMoW

IN625 IN718

CP Ti Ti6Al4V

AlSi7Mg AlSi10Mg

Cu10Sn

Au, Ag

Recent Additions

PH13-8Mo H13

HS188

IN939 Hastelloy X

TiAl3

AlSi9Cu3

Literature Alloys under study

SAF2205 SAF2507 Nitronic 310 904L

420

High Hardness

HY100 20MnCr5 4140,4340 4605,8620

IN738

M247 Nimonic 80 Nimonic 90

6061 AlFeVSi

C18000 Cu Monel K Cupronickel CuNiSiCr

Invar 36 FeCrAlY FeCo FeSi

25

Issue 131

July 2018 PCMI Journal 144

12