Page 1577 - Flipbook_SolidDesignSoutheast2020

P. 1577

FLEXIBLE CONTAINMENT TECHNOLOGIES

The basic steps for operating Materials

this easy to use system are ArmorFlex 104 is ILC Dover's proprietary film used exclusively in the

®

shown in these continuous DoverPac family of high potency flexible containment products.

®

liner process steps

®

ArmorFlex 104

• Material passes incendivity testing

• Designed and manufactured using only FDA & EU compliant materials

Continuous Liner Kit

Versatile

The Continuous Liner Kit includes:

hardware easily

mounts to vessel • Canister

discharge port • Cage

• Shroud

• 12” band clamp

• Sanitary clamp

• Gasket

The canister will attach to the vessel using a transition adapter. The

transition adapter has a nitrogen purge/vent to discharge into an inert

Continuous liner atmosphere (if required).

pack is installed

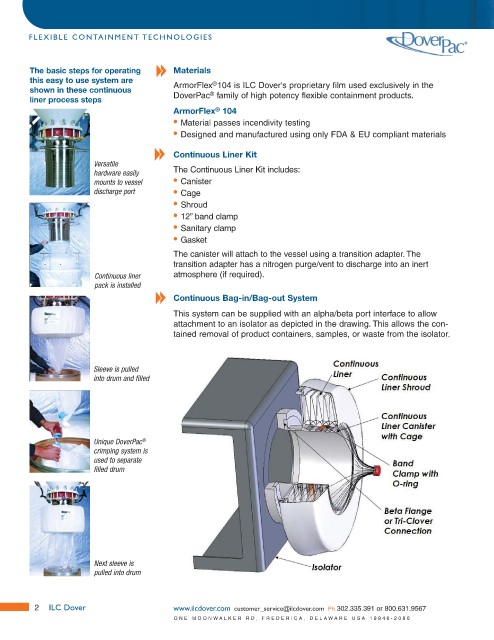

Continuous Bag-in/Bag-out System

This system can be supplied with an alpha/beta port interface to allow

attachment to an isolator as depicted in the drawing. This allows the con-

tained removal of product containers, samples, or waste from the isolator.

Sleeve is pulled

into drum and filled

Unique DoverPac ®

crimping system is

used to separate

filled drum

Next sleeve is

pulled into drum

2 ILC Dover www.ilcdover.com customer_service@ilcdover.com Ph 302.335.391 or 800.631.9567

ONE MOONW ALKER RD , FREDERICA, DELA W A RE USA 19946-2080