Page 1640 - Flipbook_SolidDesignSoutheast2020

P. 1640

Containment levels customer validated

down to less than 1 microgram/m3

on an 8-hour TWA basis.

Nanogram containment levels

achieved using DoverPac ® and

secondary containment

solvent contact resistance

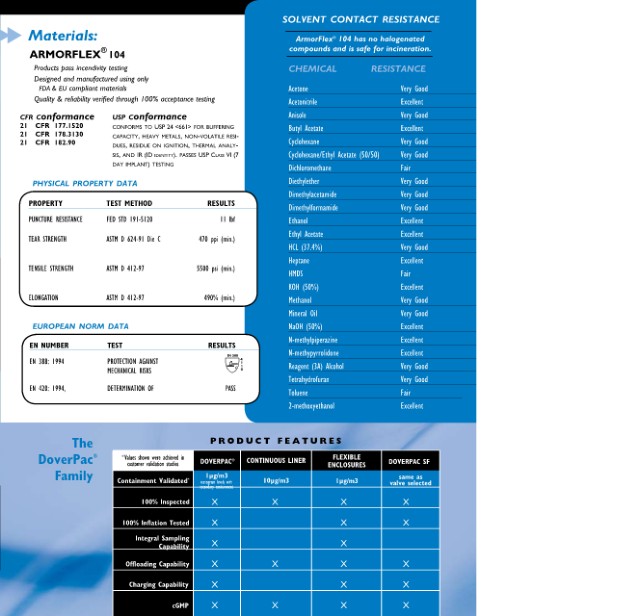

dOVeRPaC ® s s Materials: ArmorFlex ® 104 has no halogenated

COntinUOUs lineR systeM The answer to final pack off containment armorflex 104 compounds and is safe for incineration.

®

s

s

the doverPac ® continuous liner system provides the advantage of replacing packs without breaking  Products pass incendivity testing ChEMICAL RESISTAnCE

containment, unlike using inflatable heads or having operators shuffle tube stock. standard continuous  Designed and manufactured using only acetone Very good

FDA & EU compliant materials

liner pack contains 150 feet of film material and fills up to 30, 185-liter drums. the system is avail- Â Quality & reliability verified through 100% acceptance testing

able in 50, 100 and 150-foot length packs. salient features include: acetonitrile excellent

cfr conformance usp conformance anisole Very good

n Prepackaged liners save operators’ time 21 CFR 177.1520 conforms to UsP 24 <661> for bUffering Butyl acetate excellent

21 CFR 178.3130 caPacity, heavy metals, non-volatile resi-

n Individual packing maximizes in-plant cleanliness 21 CFR 182.90 dUes, residUe on ignition, thermal analy- cyclohexane Very good

n cGMP benefits over open drum filling sis, and ir (id identity). Passes UsP class vi (7 cyclohexane/ethyl acetate (50/50) Very good

n Replace packs without breaking containment day imPlant) testing Dichloromethane Fair

n Clean in place (CIP) interface incorporated physical property data Diethylether Very good

n Anti-static FDA and EU compliant materials Dimethylacetamide Very good

n Eliminates cross contamination concerns PROPeRty test MetHOd ResUlts Dimethylformamide Very good

n Interface hardware works with DoverPac ® or continuous liner system (saves capital cost) Puncture resistance FeD stD 191-5120 11 lbf ethanol excellent

n Operates in Ex environment ethyl acetate excellent

tear strength astM D 624-91 Die c 470 ppi (min.)

hcl (37.4%) Very good

heptane excellent

tensile strength astM D 412-97 5500 psi (min.)

hMDs Fair

Koh (50%) excellent

step-by-step elongation astM D 412-97 490% (min.)

usage process Methanol Very good

of our Mineral oil Very good

Continuous liner european norm data naoh (50%) excellent

en nUMbeR test ResUlts n-methylpiperazine excellent

n-methypyrrolidone excellent

versatile hardware continuous liner pack sleeve is pulled into drum unique doverpac ® next sleeve is en 388: 1994 Protection against

easily mounts to is installed and filled crimping system is used to pulled into drum reagent (3a) alcohol Very good

vessel discharge port separate filled drum Mechanical risKs

tetrahydrofuran Very good

en 420: 1994, DeterMination oF Pass toluene Fair

dOVeRPaC ® 2-methoxyethanol excellent

®

dOVeRPaC sf for Split Butterfly Valve Powder Transfer Applications

s

s

this system replaces the rigid polybottle for split butterfly valve powder the P RO duc T Fe AT u R e S

transfer applications. doverPac ® sf utilizes our flexible Containment technology, doverPac ® *Values shown were achieved in flexible

which has been widely adopted by the pharmaceutical industry. customer validation studies dOVeRPaC ® COntinUOUs lineR enClOsURes dOVeRPaC sf

family 1µg/m3 same as

n 10 and 25-liter volume Containment Validated * nanogram levels with 10µg/m3 1µg/m3 valve selected

secondary containment

n Reduced storage space compared to bottles 100% inspected X X X X

n Eliminates cleaning and validation requirements

100% inflation tested X X X

n Visual verification of product discharge

integral sampling

n Unique conical neck ensures complete product transfer Capability X X

n Restrained model accommodates .49 Bar pressure exertions X X X X

n Flexible design allows operators to manipulate sidewalls Offloading Capability

to increase product flow Charging Capability X X X

n 99.95% API recovery Model DP2116 Model DP2118

cGMP X X X X