Page 1700 - Flipbook_SolidDesignSoutheast2020

P. 1700

F lexible Containment Solution S Gui D e

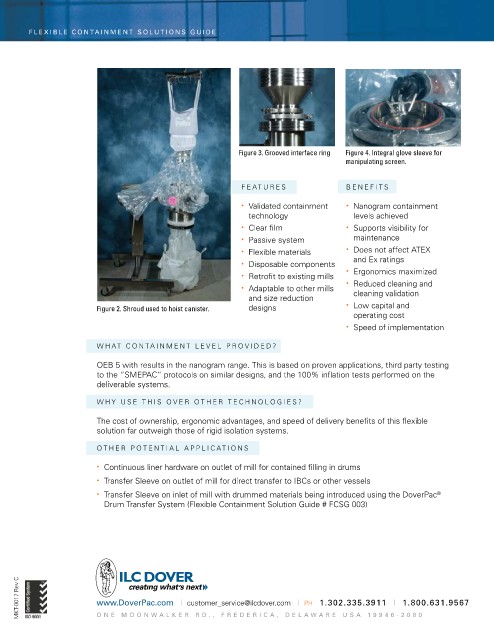

Figure 3. Grooved interface ring Figure 4. Integral glove sleeve for

manipulating screen.

F e ATU re S B e N e F i TS

• validated containment • Nanogram containment

technology levels achieved

• Clear film • Supports visibility for

• Passive system maintenance

• Flexible materials • Does not affect ATeX

and ex ratings

• Disposable components

• ergonomics maximized

• retrofit to existing mills

• reduced cleaning and

• Adaptable to other mills cleaning validation

and size reduction

Figure 2. Shroud used to hoist canister. designs • Low capital and

operating cost

• Speed of implementation

w HAT CONT A i NM e NT L eve L P r O vi D e D?

OeB 5 with results in the nanogram range. This is based on proven applications, third party testing

to the “SMePAC” protocols on similar designs, and the 100% inflation tests performed on the

deliverable systems.

w HY US e TH i S O ver OTH er T e CHNOLOG ie S?

The cost of ownership, ergonomic advantages, and speed of delivery benefits of this flexible

solution far outweigh those of rigid isolation systems.

OTH er POT e NT i AL APPL i CAT i ONS

• Continuous liner hardware on outlet of mill for contained filling in drums

• Transfer Sleeve on outlet of mill for direct transfer to iBCs or other vessels

®

• Transfer Sleeve on inlet of mill with drummed materials being introduced using the DoverPac

Drum Transfer System (Flexible Containment Solution Guide # FCSG 003)

MKT-0017 rev C www.DoverPac.com | customer_service@ilcdover.com | PH 1.302.335.3911 | 1.800.631.9567

one moon W al K e R RD., FR e D e R i C a , D ela W a R e u S a 19946-2080