Page 1758 - Flipbook_SolidDesignSoutheast2020

P. 1758

®

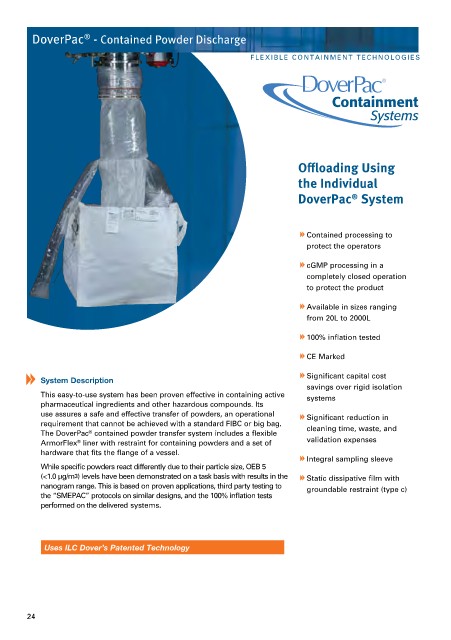

DoverPac - Contained Powder Discharge

FLEXIBLE CONTAINMENT TECHNOLOGIES

FLEXIBLE C ONTA INMENT TECHNOLOGIES

Containment

Containment

Systems

Systems

Offloading Using

the Individual

Offloading Using

DoverPac System

®

the Individual

DoverPac System

®

Contained processing to

protect the operators

Contained processing to

cGMP processing in a

protect the operators

completely closed operation

to protect the product

cGMP processing in a

completely closed operation

Available in sizes ranging

to protect the product

from 20L to 2000L

Available in sizes ranging

100% inflation tested

from 20L to 2000L

CE Marked

100% inflation tested

System Description Significant capital cost

savings over rigid isolation

This easy-to-use system has been proven effective in containing active CE Marked

systems

pharmaceutical ingredients and other hazardous compounds. Its

use assures a safe and effective transfer of powders, an operational Significant capital cost

System Description Significant reduction in

requirement that cannot be achieved with a standard FIBC or big bag. savings over rigid isolation

cleaning time, waste, and

This easy-to-use system has been proven effective in containing active systems

The DoverPac ® contained powder transfer system includes a flexible

pharmaceutical ingredients and other hazardous compounds. Its validation expenses

ArmorFlex ® liner with restraint for containing powders and a set of

hardware that fits the flange of a vessel.

use assures a safe and effective transfer of powders, an operational Significant reduction in

requirement that cannot be achieved with a standard FIBC or big bag. Integral sampling sleeve

While specific powders react differently due to their particle size, OEB 5

The DoverPac contained powder transfer system includes a flexible cleaning time, waste, and

®

(<1.0 µg/m3) levels have been demonstrated on a task basis with results in the

Static dissipative film with

®

ArmorFlex liner with restraint for containing powders and a set of validation expenses

nanogram range. This is based on proven applications, third party testing to

hardware that fits the flange of a vessel. groundable restraint (type c)

the “SMEPAC” protocols on similar designs, and the 100% inflation tests

performed on the delivered systems. Integral sampling sleeve

While specific powders react differently due to their particle size, OEB 5

(<1.0 µg/m3) levels have been demonstrated on a task basis with results in the Static dissipative film with

Uses ILC Dover’s Patented Technology

nanogram range. This is based on proven applications, third party testing to groundable restraint (type c)

the “SMEPAC” protocols on similar designs, and the 100% inflation tests

performed on the delivered systems.

www.doverpac.com customer_service@ilcdover.com Ph 1.302.335.3911 or 1.800.631.9567

Uses ILC Dover’s Patented Technology ILC Dover 1

ONE M OONW ALKER RD., FREDERICA, D ELA W ARE U SA 19946-2080

24