Page 2059 - Flipbook_SolidDesignSoutheast2020

P. 2059

Plough Mixers

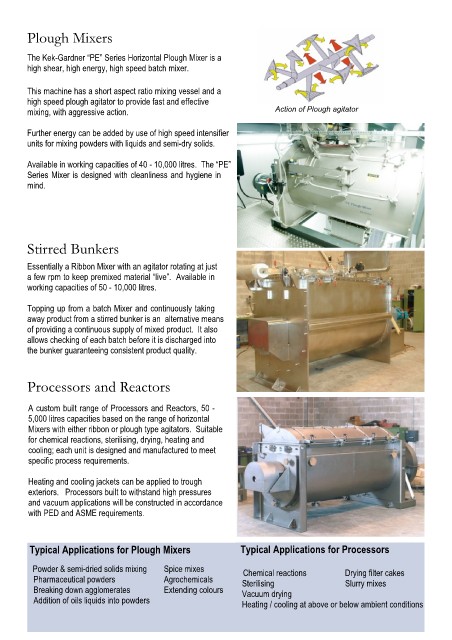

The Kek-Gardner “PE” Series Horizontal Plough Mixer is a

high shear, high energy, high speed batch mixer.

This machine has a short aspect ratio mixing vessel and a

high speed plough agitator to provide fast and effective

mixing, with aggressive action. Action of Plough agitator

Further energy can be added by use of high speed intensifier

units for mixing powders with liquids and semi-dry solids.

Available in working capacities of 40 - 10,000 litres. The “PE”

Series Mixer is designed with cleanliness and hygiene in

mind.

Stirred Bunkers

Essentially a Ribbon Mixer with an agitator rotating at just

a few rpm to keep premixed material “live”. Available in

working capacities of 50 - 10,000 litres.

Topping up from a batch Mixer and continuously taking

away product from a stirred bunker is an alternative means

of providing a continuous supply of mixed product. It also

allows checking of each batch before it is discharged into

the bunker guaranteeing consistent product quality.

Processors and Reactors

A custom built range of Processors and Reactors, 50 -

5,000 litres capacities based on the range of horizontal

Mixers with either ribbon or plough type agitators. Suitable

for chemical reactions, sterilising, drying, heating and

cooling; each unit is designed and manufactured to meet

specific process requirements.

Heating and cooling jackets can be applied to trough

exteriors. Processors built to withstand high pressures

and vacuum applications will be constructed in accordance

with PED and ASME requirements.

Typical Applications for Plough Mixers Typical Applications for Processors

Powder & semi-dried solids mixing Spice mixes Chemical reactions Drying filter cakes

Pharmaceutical powders Agrochemicals Sterilising Slurry mixes

Breaking down agglomerates Extending colours Vacuum drying

Addition of oils liquids into powders

Heating / cooling at above or below ambient conditions