Page 2874 - Flipbook_SolidDesignSoutheast2020

P. 2874

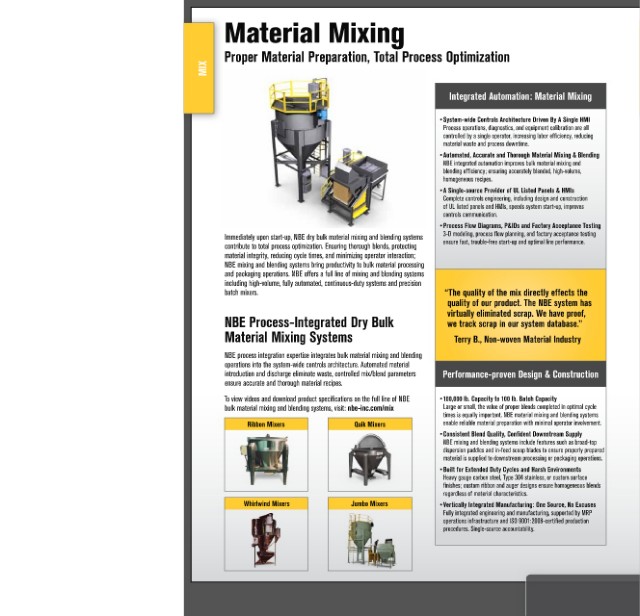

Material Mixing Material Weighing

Proper Material Preparation, Total Process Optimization NTEP-certified Accurate: No Waste, No Re-work, No Doubts

MIx WEIGH

Integrated Automation: Material Mixing Integrated Automation: Material Weighing

• System-wide Controls Architecture Driven By A Single HMI • A Single, Menu-driven HMI Centralizes System-wide Operations

Process operations, diagnostics, and equipment calibration are all Control, communication, monitoring, and reporting of process operations

controlled by a single operator, increasing labor efficiency, reducing are directed from a single, menu-driven HMI, increasing labor efficiency

material waste and process downtime. and reducing downtime.

• Automated, Accurate and Thorough Material Mixing & Blending • Automated, Certified Weighing: Accurate to +/- .01%

NBE integrated automation improves bulk material mixing and NBE NTEP-certified weigh devices provide automated assurance that

blending efficiency; ensuring accurately blended, high-volume, filled weights are certified accurate, material volume is precise, and

homogeneous recipes. material waste is eliminated.

• A Single-source Provider of UL Listed Panels & HMIs • Process-specific PLCs and HMIs designed & Built by NBE

Complete controls engineering, including design and construction A single-source provider of automation controls and programming,

of UL listed panels and HMIs, speeds system start-up, improves NBE integrated automation increases system start-up efficiency

controls communication. improves equipment communication, and enhances operator safety.

• Process Flow Diagrams, P&IDs and Factory Acceptance Testing • Standardized Controls Programming: Process Optimization

Immediately upon start-up, NBE dry bulk material mixing and blending systems 3-D modeling, process flow planning, and factory acceptance testing NBE integrated automation expands controls functionality. Sta

ensure fast, trouble-free start-up and optimal line performance.

programming improves total process optimization.

contribute to total process optimization. Ensuring thorough blends, protecting customer specifications, increasing material costs, plant safety directives, and stringent

material integrity, reducing cycle times, and minimizing operator interaction; supply chain limitations. NBE weigh systems provide reliable, repeatable, precision-

NBE mixing and blending systems bring productivity to bulk material processing weighed bulk containers, properly supplied process lines, and accurately weighed

and packaging operations. NBE offers a full line of mixing and blending systems finished packages. NBE enables even greater process efficiency by linking NTEP-

including high-volume, fully automated, continuous-duty systems and precision “Our batch ingredient weights are critical; we certified weighing into system-wide communications, sensing, monitoring, and

batch mixers. “The quality of the mix directly effects the used to weigh them by hand. The accuracy of reporting. Automated material weighing, certified to +/- .01% accuracy, optimizes

quality of our product. The NBE system has total line throughput and improves resource management.

virtually eliminated scrap. We have proof, NBE’s automated equipment took a very labor

NBE Process-Integrated Dry Bulk we track scrap in our system database.” intensive step and automated it to where all NBE Process-Integrated Dry Bulk

we do now is monitor the system.”

Material Mixing Systems Terry B., Non-woven Material Industry John D., Building Components Industry Material Weigh Systems

NBE process integration expertise integrates bulk material mixing and blending From material introduction to final packaging, in continuous or batch mode, NBE

operations into the system-wide controls architecture. Automated material weigh systems leverage the advantages of NBE integrated automation. Available

introduction and discharge eliminate waste, controlled mix/blend parameters Performance-proven Design & Construction Performance-proven Design & Construction NTEP-certified weigh accuracy of +/- .01%, adds i

ensure accurate and thorough material recipes. accuracy and reduction in material waste, package re-work, labor, and inventory.

To view videos and download product specifications on the full line of NBE • 100,000 lb. Capacity to 100 lb. Batch Capacity • Precision Fabrication Ensures Consistent Scale Accuracy To view videos and dow

bulk material mixing and blending systems, visit: nbe-inc.com/mix Large or small, the value of proper blends completed in optimal cycle Design-stage integration of NBE NTEP-certified weigh devices bulk ma

times is equally important. NBE material mixing and blending systems ensures +/- .01% accuracy; unmatched by common, bolt-on,

Ribbon Mixers Quik Mixers enable reliable material preparation with minimal operator involvement. third-party scale components. Gain-in-Weight Loss-in-Weight

• Consistent Blend Quality, Confident Downstream Supply • Nationally Recognized Weigh Systems Certification

NBE mixing and blending systems include features such as broad-top NBE NTEP-certified weigh systems comply with rigorous certification

dispersion paddles and in-feed scoop blades to ensure properly prepared test standards; producing over 7,000 consecutive weigh cycles within

material is supplied to downstream processing or packaging operations. a +/- .01% weight tolerance.

• Built for Extended Duty Cycles and Harsh Environments • 6” x 4” x 5/16” Structural Tubing; Heavy Gauge Sheet & Plate

Heavy gauge carbon steel, Type 304 stainless, or custom surface Built for extended duty cycles and harsh process environments; heavy-

finishes; custom ribbon and auger designs ensure homogeneous blends duty carbon and stainless steel construction optimize performance.

regardless of material characteristics. • Exceptional Quality, Strict Standards, Immediate Productivity

Whirlwind Mixers Jumbo Mixers • Vertically Integrated Manufacturing: One Source, No Excuses MRP-linked laser tables, high-speed machining centers, and in-house Weigh Hoppers Weigh Conveyors

Fully integrated engineering and manufacturing, supported by MRP UL listed panel building enable NBE to manufacture to exacting fit

operations infrastructure and ISO 9001:2008-certified production and finish within tight timelines.

procedures. Single-source accountability.