Page 2994 - Flipbook_SolidDesignSoutheast2020

P. 2994

I I

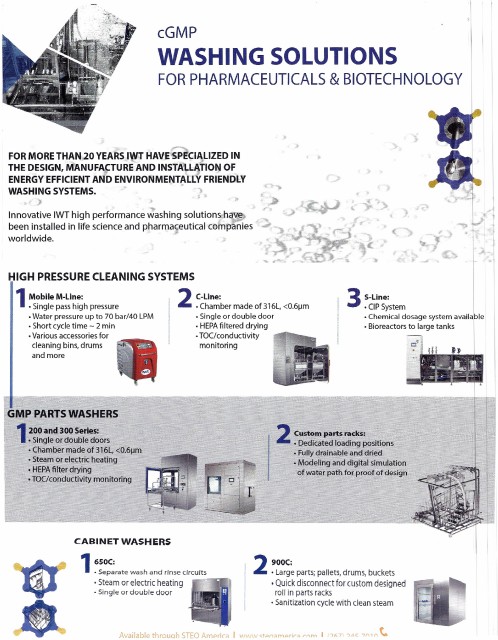

cGMP

WASHING SOLUTIONS

FOR PHARMACEUTICALS & BIOTECHNOLOGY

.•.

FOR MORE THAN 20 YEARS IWT HAVE SPECIALIZED IN

-

THE DESIGN, MANUFACTURE AND INSTALLATION OF

ENERGY EFFICIENT AND ENVIRONMENTALLY FRIENDLY

WASHING SYSTEMS. i

JO

Innovative IWT high performance washing solutions have

been installed in life science and pharmaceutical companies

worldwide. ;.

HIGH PRESSURE CLEANING SYSTEMS

1 Mobile M-Line: 2 C-Line: 3 S-line:

• Single passhigh pressure

•Water pressure up to 70 bar/40 LPM • Chamber made of 316L, <O.6I-1m • ClPSystem

• Chemical dosage system availa

• Single or double door

• Short cycle time - 2 min • HEPAfiltered drying • Bioreactors to large tanks

• Various accessoriesfor •TOC/conductivity

cleaning bins, drums monitoring

and more

GMP PARTS WASHERS

2 Custom parts raci(s: .

~1~~i~;I~~:~~~61~~~ors • Dedicated loading positions

.• Chamber made of 316L, <O.6~m • Fully drainable and dried

• Steam or electric heating • Modeling and digital simulation

• HEPAfilter drying 'of water path for proof of design

•TOC/conductivity monitoring

CABINET WASHERS

1 650C: 900C:

• Separate wash and rinse circuits

• Steam or electric heating _,..--.."I"IP' ..•• 2 • Large parts; pallets, drums, buckets

• Quick disconnect for custom designed

• Single or double door roll in parts racks

• Sanitization cycle with clean steam

Available throuah STEOArnerk a I \AlWIN ,tl>,,;:,mAyir;> rrH.,.., I lit:.7\ ,A C 7n 1 n (.