Page 3011 - Flipbook_SolidDesignSoutheast2020

P. 3011

AERO-FLEX Flexible Screw Conveyors

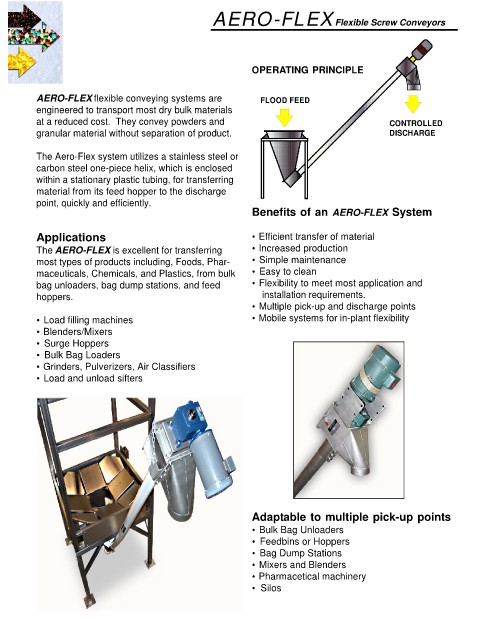

OPERATING PRINCIPLE

AERO-FLEX flexible conveying systems are FLOOD FEED

engineered to transport most dry bulk materials

at a reduced cost. They convey powders and CONTROLLED

granular material without separation of product. DISCHARGE

The Aero-Flex system utilizes a stainless steel or

carbon steel one-piece helix, which is enclosed

within a stationary plastic tubing, for transferring

material from its feed hopper to the discharge

point, quickly and efficiently.

Benefits of an AERO-FLEX System

Applications Efficient transfer of material

The AERO-FLEX is excellent for transferring Increased production

most types of products including, Foods, Phar- Simple maintenance

maceuticals, Chemicals, and Plastics, from bulk Easy to clean

bag unloaders, bag dump stations, and feed Flexibility to meet most application and

hoppers. installation requirements.

Multiple pick-up and discharge points

Load filling machines Mobile systems for in-plant flexibility

Blenders/Mixers

Surge Hoppers

Bulk Bag Loaders

Grinders, Pulverizers, Air Classifiers

Load and unload sifters

Adaptable to multiple pick-up points

Bulk Bag Unloaders

Feedbins or Hoppers

Bag Dump Stations

Mixers and Blenders

Pharmacetical machinery

Silos