Page 3239 - Flipbook_SolidDesignSoutheast2020

P. 3239

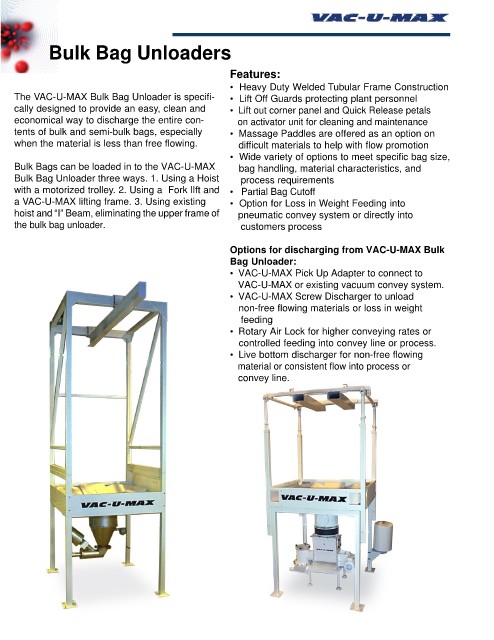

Bulk Bag Unloaders

Features:

Heavy Duty Welded Tubular Frame Construction

The VAC-U-MAX Bulk Bag Unloader is specifi- Lift Off Guards protecting plant personnel

cally designed to provide an easy, clean and Lift out corner panel and Quick Release petals

economical way to discharge the entire con- on activator unit for cleaning and maintenance

tents of bulk and semi-bulk bags, especially Massage Paddles are offered as an option on

when the material is less than free flowing. difficult materials to help with flow promotion

Wide variety of options to meet specific bag size,

Bulk Bags can be loaded in to the VAC-U-MAX bag handling, material characteristics, and

Bulk Bag Unloader three ways. 1. Using a Hoist process requirements

with a motorized trolley. 2. Using a Fork lIft and Partial Bag Cutoff

a VAC-U-MAX lifting frame. 3. Using existing Option for Loss in Weight Feeding into

hoist and I Beam, eliminating the upper frame of pneumatic convey system or directly into

the bulk bag unloader. customers process

Options for discharging from VAC-U-MAX Bulk

Bag Unloader:

VAC-U-MAX Pick Up Adapter to connect to

VAC-U-MAX or existing vacuum convey system.

VAC-U-MAX Screw Discharger to unload

non-free flowing materials or loss in weight

feeding

Rotary Air Lock for higher conveying rates or

controlled feeding into convey line or process.

Live bottom discharger for non-free flowing

material or consistent flow into process or

convey line.