Page 524 - Flipbook_SolidDesignSoutheast2020

P. 524

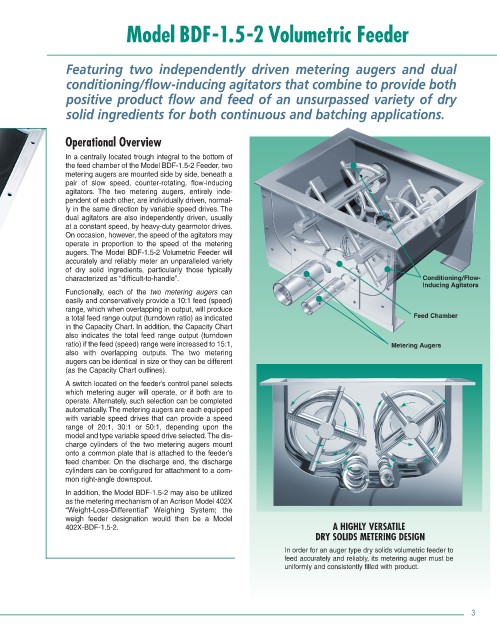

ModelBDF-1.5-2 Volumetric Feeder

Featuring two independently driven metering augers and dual

conditioning/flow-inducing agitators that combine to provide both

positive product flow and feed of an unsurpassed variety of dry

solid ingredients for both continuous and batching applications.

Operational Overview

In a centrally located trough integral to the bottom of

the feed chamber of the Model BDF-1.5-2 Feeder, two •

metering augers are mounted side by side, beneath a

pair of slow speed, counter-rotating, flow-inducing

agitators. The two metering augers, entirely inde-

pendent of each other, are individually driven, normal-

ly in the same direction by variable speed drives. The

dual agitators are also independently driven, usually

at a constant speed, by heavy-duty gearmotor drives.

On occasion, however, the speed of the agitators may

operate in proportion to the speed of the metering

augers. The Model BDF-1.5-2 Volumetric Feeder will

accurately and reliably meter an unparalleled variety •

of dry solid ingredients, particularly those typically • •

characterized as “difficult-to-handle”. Conditioning/Flow-

Inducing Agitators

Functionally, each of the two metering augers can

easily and conservatively provide a 10:1 feed (speed) •

range, which when overlapping in output, will produce

a total feed range output (turndown ratio) as indicated Feed Chamber

in the Capacity Chart. In addition, the Capacity Chart

also indicates the total feed range output (turndown

ratio) if the feed (speed) range were increased to 15:1, Metering Augers

also with overlapping outputs. The two metering

augers can be identical in size or they can be different

(as the Capacity Chart outlines).

A switch located on the feeder’s control panel selects

which metering auger will operate, or if both are to

operate. Alternately, such selection can be completed

automatically.The metering augers are each equipped

with variable speed drives that can provide a speed

range of 20:1, 30:1 or 50:1, depending upon the

model and type variable speed drive selected.The dis-

charge cylinders of the two metering augers mount

onto a common plate that is attached to the feeder’s

feed chamber. On the discharge end, the discharge

cylinders can be configured for attachment to a com-

mon right-angle downspout.

In addition, the Model BDF-1.5-2 may also be utilized

as the metering mechanism of an Acrison Model 402X

“Weight-Loss-Differential” Weighing System; the

weigh feeder designation would then be a Model

402X-BDF-1.5-2. A HIGHLY VERSATILE

DRY SOLIDS METERING DESIGN

In order for an auger type dry solids volumetric feeder to

feed accurately and reliably, its metering auger must be

uniformly and consistently filled with product.

3