Page 548 - Flipbook_SolidDesignSoutheast2020

P. 548

Acrison ® VOLUMETRIC

Acrison ® FEEDERS

Acrison ® Model W-105 Series

For Dry Chemicals

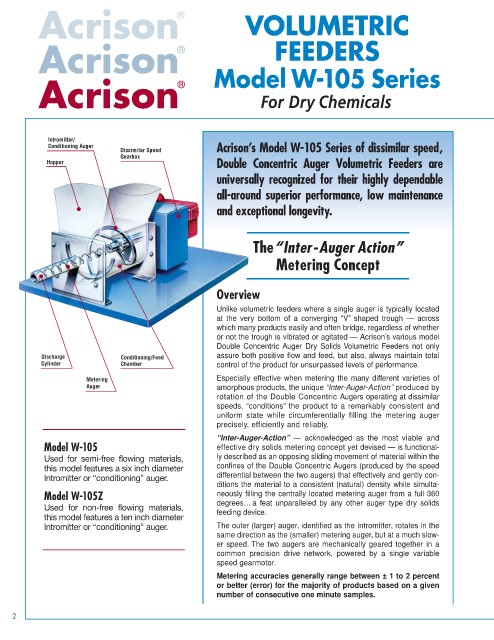

Intromitter/

Conditioning Auger Acrison’s Model W-105 Series of dissimilar speed,

Dissimilar Speed

Gearbox

Hopper Double Concentric Auger Volumetric Feeders are

universally recognized for their highly dependable

all-around superior performance, low maintenance

• and exceptional longevity.

•

•

The“Inter-Auger Action”

• • Metering Concept

•

Overview

Unlike volumetric feeders where a single auger is typically located

at the very bottom of a converging “V” shaped trough — across

which many products easily and often bridge, regardless of whether

or not the trough is vibrated or agitated — Acrison’s various model

Double Concentric Auger Dry Solids Volumetric Feeders not only

Discharge Conditioning/Feed assure both positive flow and feed, but also, always maintain total

Cylinder Chamber control of the product for unsurpassed levels of performance.

Metering Especially effective when metering the many different varieties of

Auger amorphous products, the unique “Inter-Auger-Action” produced by

rotation of the Double Concentric Augers operating at dissimilar

speeds, “conditions” the product to a remarkably consistent and

uniform state while circumferentially filling the metering auger

precisely, efficiently and reliably.

“Inter-Auger-Action” — acknowledged as the most viable and

Model W-105 effective dry solids metering concept yet devised — is functional-

Used for semi-free flowing materials, ly described as an opposing sliding movement of material within the

this model features a six inch diameter confines of the Double Concentric Augers (produced by the speed

Intromitter or “conditioning” auger. differential between the two augers) that effectively and gently con-

ditions the material to a consistent (natural) density while simulta-

Model W-105Z neously filling the centrally located metering auger from a full 360

degrees… a feat unparalleled by any other auger type dry solids

Used for non-free flowing materials, feeding device.

this model features a ten inch diameter

Intromitter or “conditioning” auger. The outer (larger) auger, identified as the Intromitter, rotates in the

same direction as the (smaller) metering auger, but at a much slow-

er speed. The two augers are mechanically geared together in a

common precision drive network, powered by a single variable

speed gearmotor.

Metering accuracies generally range between ± 1 to 2 percent

or better (error) for the majority of products based on a given

number of consecutive one minute samples.

2