Page 672 - Flipbook_SolidDesignSoutheast2020

P. 672

Auger Fillers

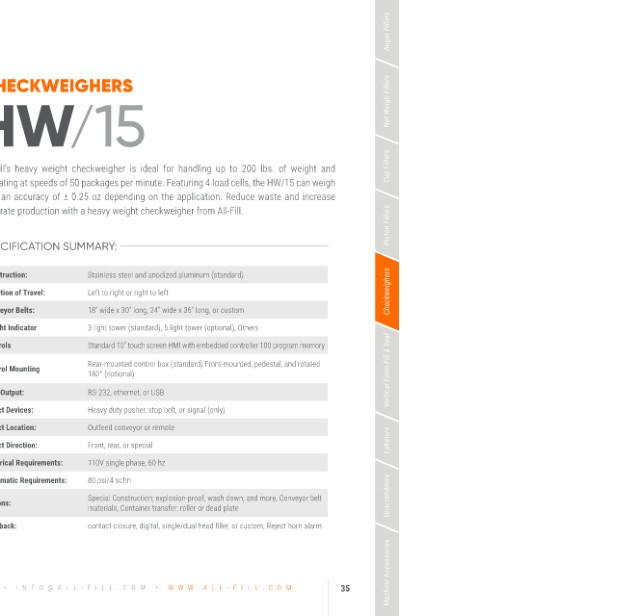

CHECKWEIGHERS

Net Weigh Fillers

All-Fill’s heavy weight checkweigher is ideal for handling up to 200 lbs. of weight and Cup Fillers

operating at speeds of 50 packages per minute. Featuring 4 load cells, the HW/15 can weigh

with an accuracy of ± 0.25 oz depending on the application. Reduce waste and increase

accurate production with a heavy weight checkweigher from All-Fill.

Piston Fillers

SPECIFICATION SUMMARY:

Construction: Stainless steel and anodized aluminum (standard)

Direction of Travel: Left to right or right to left Checkweighers

Conveyor Belts: 18” wide x 30” long, 24” wide x 36” long, or custom

Weight Indicator 3 light tower (standard), 5 light tower (optional), Others

Controls Standard 10” touch screen HMI with embedded controller 100 program memory

Control Mounting Rear-mounted control box (standard) Front-mounted, pedestal, and rotated Vertical Form Fill & Seal

180° (optional)

Data Output: RS-232, ethernet, or USB

Reject Devices: Heavy duty pusher, stop belt, or signal (only)

Reject Location: Outfeed conveyor or remote

Reject Direction: Front, rear, or special Labelers

Electrical Requirements: 110V single phase, 60 hz

HW/15 Pneumatic Requirements: 80 psi/4 scfm

Heavy Duty Large Package Weigher Special Construction; explosion-proof, wash down, and more, Conveyor belt Unscramblers

(Formerly Alpha Checkweighers) Options:

materials, Container transfer: roller or dead plate

Feedback: contact closure, digital, single/dual head filler, or custom, Reject horn alarm

Machine Accessories

418 C REAMER Y W A Y , EXT ON P A • 610 . 524 . 7350 • INFO @ ALL - FILL . C OM • WWW . ALL - FILL . C OM 35