Page 771 - Flipbook_SolidDesignSoutheast2020

P. 771

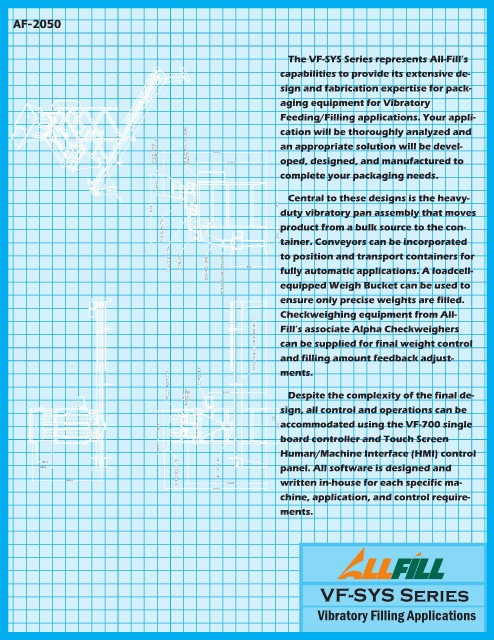

AF-2050

The VF-SYS Series represents All-Fill’s

capabilities to provide its extensive de-

sign and fabrication expertise for pack-

aging equipment for Vibratory

Feeding/Filling applications. Your appli-

cation will be thoroughly analyzed and

INFEED HOPPER INFEED HOPPER (APPROX 3.0 CU FT) (APPROX 3.0 CU FT) REF. ELECTRICAL ENCLOSURE REF. ELECTRICAL ENCLOSURE (30X24X10) (30X24X10) 90.19 90.19 60.51 60.51 an appropriate solution will be devel-

oped, designed, and manufactured to

complete your packaging needs.

18.00 18.00

Central to these designs is the heavy-

40.00 40.00

60.03 60.03

duty vibratory pan assembly that moves

MAIN BULKK TRAY MAIN BULKK TRAY 13.44 13.44 product from a bulk source to the con-

tainer. Conveyors can be incorporated

BULK/DRIBBLE TRAY BULK/DRIBBLE TRAY WEIGHBUCKET WEIGHBUCKET DISCHARGE HOPPER DISCHARGE HOPPER REMOVABLE DISCHARGE TUBE REMOVABLE DISCHARGE TUBE 31.01 31.01 to position and transport containers for

fully automatic applications. A loadcell-

equipped Weigh Bucket can be used to

ensure only precise weights are filled.

Checkweighing equipment from All-

CONVEYOR SHOWN FOR REFERENCE ONLY CONVEYOR SHOWN FOR REFERENCE ONLY Fill’s associate Alpha Checkweighers

can be supplied for final weight control

and filling amount feedback adjust-

PRODUCT RESTRICTOR PRODUCT RESTRICTOR 12.00" 12.00" BUCKET/TRAY BUCKET/TRAY CENTER CENTER CONTROL BOX CONTROL BOX 50.51 50.51 ments.

Despite the complexity of the final de-

sign, all control and operations can be

15.50 15.50

26.00 26.00 31.00 31.00 accommodated using the VF-700 single

board controller and Touch Screen

12.00 12.00

Human/Machine Interface (HMI) control

INFEED SIDE CHUTE INFEED SIDE CHUTE REF. CONTAINER REF. CONTAINER 68.45 68.45 panel. All software is designed and

13.00

13.00

18.00

18.00

written in-house for each specific ma-

60.06

60.06

89.19

89.19

chine, application, and control require-

ments.

VF-SYS Series

Vibratory Filling Applications