Page 21 - PDZA Sustainable Aquarium Brochure

P. 21

HEATING AND COOLING

There are other energy recovery strategies such Referring back to the annual heating and cooling

as enthalpy wheels, which can provide much energy charts and including the heat recovered

higher energy recovery rates, ranging from 70% from the exhaust air, we can see additional time

to 85%. However, they come with risk of cross each year where we are benefiting from the higher

contamination between the exhaust and outside efficiency of using the exhaust air stream as a heat

air intake streams. For this project, we are using source rather than ambient air. (See Figure 7).

the chilled water loop and our heat pump’s ability

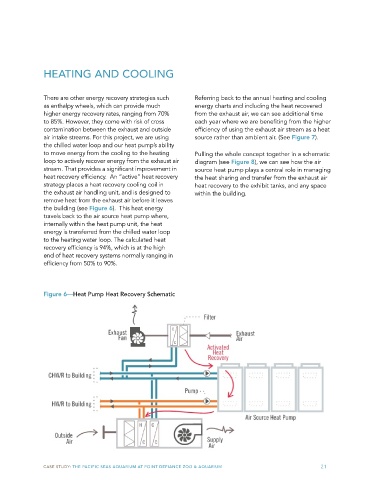

to move energy from the cooling to the heating Pulling the whole concept together in a schematic

loop to actively recover energy from the exhaust air diagram (see Figure 8), we can see how the air

stream. That provides a significant improvement in source heat pump plays a central role in managing

heat recovery efficiency. An “active” heat recovery the heat sharing and transfer from the exhaust air

strategy places a heat recovery cooling coil in heat recovery to the exhibit tanks, and any space

the exhaust air handling unit, and is designed to within the building.

remove heat from the exhaust air before it leaves

the building (see Figure 6). This heat energy

travels back to the air source heat pump where,

internally within the heat pump unit, the heat

energy is transferred from the chilled water loop

to the heating water loop. The calculated heat

recovery efficiency is 94%, which is at the high

end of heat recovery systems normally ranging in

efficiency from 50% to 90%.

Figure 6—Heat Pump Heat Recovery Schematic

CASE STUDY: THE PACIFIC SEAS AQUARIUM AT POINT DEFIANCE ZOO & AQUARIUM 21