Page 7 - Warehouse 1 to 9

P. 7

6 7

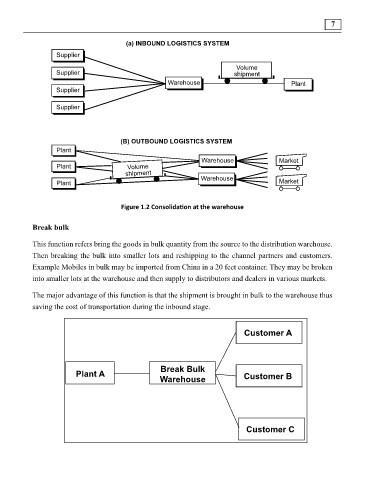

Inventory Holding – Meeting Demand and Supply (a) INBOUND LOGISTICS SYSTEM

Supplier

The actual demand of the product always varies from the forecasted demand. In case the desired Volume

product is not available in the market or the retail counter, it is loss of sales to the company. Supplier shipment

Most of the manufacturing companies follow batch manufacturing where they manufacture various Supplier Warehouse Plant

models in batches. Similarly, when imports occur, it happens in lot sizes. Hence, the supply is never

a straight line. To manage the variations between demand and supply, companies need to hold Supplier

inventory of various products. The most fundamental function of a warehouse is to hold inventory

so that it can match demand with the supply.

(B) OUTBOUND LOGISTICS SYSTEM

Consolidation Plant

Warehouse Market

In this function, a warehouse receives goods from various plants, stores them and combines them as Plant Volume

single shipment to meet the requirement of the customer. For example, a consumer durable company Plant shipment Warehouse Market

manufactures TV, Refrigerator, Washing Machines at different factories. They all get combined at

the warehouse. When the distributor places combined order for TV, Freeze and washing Machine,

they all are shipped together as one order. Figure 1.2 Consolidation at the warehouse

Alternatively, on the inward supply chain side, a warehouse outside the factory may receive goods Break bulk

from various suppliers and consolidate them and ship as single unit to the factory. An automobile This function refers bring the goods in bulk quantity from the source to the distribution warehouse.

factory may have a warehouse outside or inside the factory. It receives the material from various Then breaking the bulk into smaller lots and reshipping to the channel partners and customers.

suppliers. It consolidates material from various suppliers and move them to assembly line based on Example Mobiles in bulk may be imported from China in a 20 feet container. They may be broken

the model getting manufactured. into smaller lots at the warehouse and then supply to distributors and dealers in various markets.

The major advantage of this function is that the shipment is brought in bulk to the warehouse thus

saving the cost of transportation during the inbound stage.

Consolidation

Plant A Customer Customer A

Consolidation

Plant B warehouses A B C

Break Bulk

Plant A Warehouse Customer B

Plant C

Figure 1.1 Inbound Consolidation

Customer C