Page 76 - Nicolaes Witsen & Shipbuilding in the Dutch Golden Age

P. 76

Chapter Two

compass could not reach. Then the rst side is hewn o to nothing, and every 7 inches a hole is drilled, one inch from the side, outside and at the inside to noth- ing. On the hewn side then moss is laid , which is laid onwithpitch,thenthe plankisputinposition,and fastened to the k eel. The outside of the plank is then lined as desired, or hewn o and then another is put against it. After this with a scraper the uneven places are marked even, below and also above, and after these havebeenremoved,hewno ,andputbackonagain, and it ts well, then the cleats are tak en with which the planks are held together, put inside and out about three or four feet from one another, and so done, here and there on the keel and garboard strake also a cleat is hammered, coming above the k eel, and closing on the keel as well as on the garboard strak e, and so fas- tened it on the keel.

17. Make the Garboard Strake

The only reference in Witsen’s book to the differenc e in the building methods of the Meuse and Amsterdam re- gions is the remark in passage 150 II 33. It is curious that he does not mention the differ ence in building method

(frame-first versus shell-first), but only the fact that in Rot- terdam the garboard strake was left out until the last min- ute just so the rubbish could be removed through the hole in the bottom!

Van Yk, on the other hand, is more explicit in his com- ment on the northern building method: “. . . where one is used to shape the bottom of the ship not with ribbands, as is done at the side of Meuse, but with the planks them- selves which go around the ship” (Van Yk, p. 70). Whether the difference was unknown to Witsen or he simp ly did not consider it worth mentioning is not clear.

A line was stretched between stem and stern. This was the most important point of measurement during the rest of the building process. Every shipwright (and model builder) knows how difficult it is to take measurements in a ship, where no straight line is to be found. This also led to many problems in the interpret ation of the me asure- ments of the pin as. Understanding or est ablishing the points of m easurement was often a probl em, which was solved mainly by means of the model.

The shipbuilderwouldfi rst lay downtheg arboard strake, the first plank at each side of the keel. Anyone who reads the description of the w ay in whic h the shipwright checked how well the garboard strake fitted into the rab-

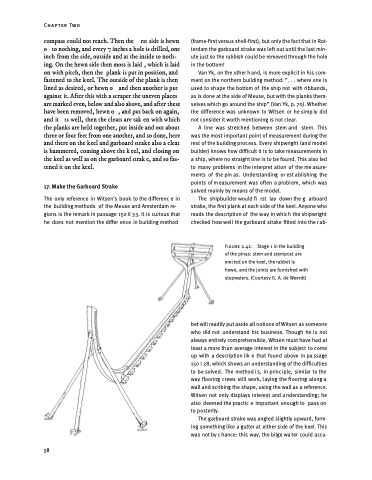

Figure 2.42. Stage 1 in the building of the pinas: stem and sternpost are erected on the keel, the rabbet is hewn, and the joints are furnished with stopwaters. (Courtesy G. A. de Weerdt)

bet will readily put aside all notions of Witsen as someone who did not understand his business. Though he i s not always entirely comprehensible, Witsen must have had at least a more than average interest in the subject to come up with a description lik e that found above in pa ssage 150 I 28, which shows an understanding of the difficulties to be solved. The method i s, in princ iple, similar to the way flooring crews still work, l aying the fl ooring along a wall and scribing the shape, using the wall as a reference. Witsen not only displays interest and u nderstanding; he also deemed the practic e important enough to pass on to posterity.

The garboard strake was angled slightly upward, form- ing something like a gutter at either side of the keel. This was not by c hance: this way, the bilge wa ter could accu-

58