Page 518 - The ROV Manual - A User Guide for Remotely Operated Vehicles 2nd edition

P. 518

19.2 Manipulator types 515

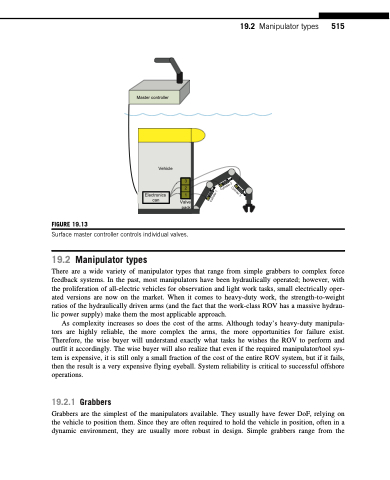

FIGURE 19.13

Master controller

Vehicle

3

2

1

Valve pack

Electronic can

s

Surface master controller controls individual valves.

19.2 Manipulator types

There are a wide variety of manipulator types that range from simple grabbers to complex force feedback systems. In the past, most manipulators have been hydraulically operated; however, with the proliferation of all-electric vehicles for observation and light work tasks, small electrically oper- ated versions are now on the market. When it comes to heavy-duty work, the strength-to-weight ratios of the hydraulically driven arms (and the fact that the work-class ROV has a massive hydrau- lic power supply) make them the most applicable approach.

As complexity increases so does the cost of the arms. Although today’s heavy-duty manipula- tors are highly reliable, the more complex the arms, the more opportunities for failure exist. Therefore, the wise buyer will understand exactly what tasks he wishes the ROV to perform and outfit it accordingly. The wise buyer will also realize that even if the required manipulator/tool sys- tem is expensive, it is still only a small fraction of the cost of the entire ROV system, but if it fails, then the result is a very expensive flying eyeball. System reliability is critical to successful offshore operations.

19.2.1 Grabbers

Grabbers are the simplest of the manipulators available. They usually have fewer DoF, relying on the vehicle to position them. Since they are often required to hold the vehicle in position, often in a dynamic environment, they are usually more robust in design. Simple grabbers range from the

Cylinder 3

Cylinder 2

Cylinder 1