Page 29 - PowerPoint Sunusu

P. 29

klebstoffe montage technik !

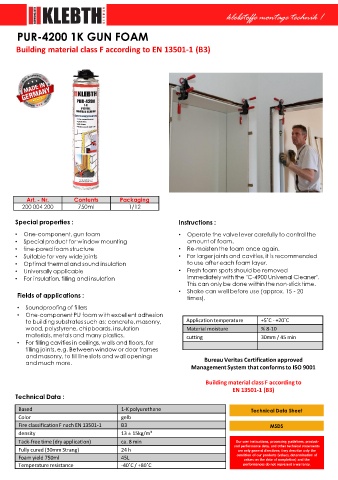

PUR-4200 1K GUN FOAM

Building material class F according to EN 13501-1 (B3)

Art. - Nr. Contents Packaging

200 004 200 750ml 1/12

Special properties : Instructions :

• One-component, gun foam • Operate the valve lever carefully to control the

• Special product for window mounting amount of foam.

• fine-pored foam structure • Re-moisten the foam once again.

• Suitable for very wide joints • For larger joints and cavities, it is recommended

• Optimal thermal and sound insulation to use after each foam layer.

• Universally applicable • Fresh foam spots should be removed

• For insulation, filling and insulation immediately with the "C-4900 Universal Cleaner".

This can only be done within the non-stick time.

• Shake can well before use (approx. 15 - 20

Fields of applications : times).

• Soundproofing of fillers

• One-component PU foam with excellent adhesion

to building substrates such as: concrete, masonry, Application temperature +5˚C - +20˚C

wood, polystyrene, chipboards, insulation Material moisture % 8-10

materials, metals and many plastics. cutting 30mm / 45 min

• For filling cavities in ceilings, walls and floors, for

filling joints, e.g. Between window or door frames

and masonry, to fill line slots and wall openings

and much more. Bureau Veritas Certification approved

Management System that conforms to ISO 9001

Building material class F according to

EN 13501-1 (B3)

Technical Data :

Based 1-K polyurethane Technical Data Sheet

Color gelb

Fire classificationF nach EN 13501-1 B3 MSDS

density 13 ± 15kg/m³

Tack-free time (dry application) ca. 8 min Our user instructions, processing guidelines, product-

and performance data, and other technical statements

Fully cured (30mm Strang) 24 h are only general directives; they describe only the

condition of our products (values, determination of

Foam yield 750ml 45L values on the date of completion) and the

Temperature resistance -40˚C / +80˚C performances do not represent a warranty.