Page 3 - PowerPoint Sunusu

P. 3

klebstoffe montage technik !

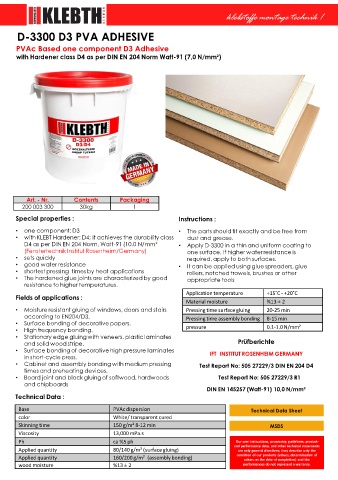

D-3300 D3 PVA ADHESIVE

PVAc Based one component D3 Adhesive

with Hardener class D4 as per DIN EN 204 Norm Watt-91 (7,0 N/mm²)

Art. - Nr. Contents Packaging

200 003 300 30kg 1

Special properties : Instructions :

• one component: D3 • The parts should fit exactly and be free from

• with KLEBT Hardener: D4; it achieves the durability class dust and grease.

D4 as per DIN EN 204 Norm, Watt-91 (10.0 N/mm² • Apply D-3300 in a thin and uniform coating to

(Fenstertechnik Institut Rosenheim/Germany) one surface. If higher water resistance is

• sets quickly required, apply to both surfaces.

• good water resistance • It can be applied using glue spreaders, glue

• shortest pressing times by heat applications rollers, notched trowels, brushes or other

• The hardened glue joints are characterized by good appropriate tools

resistance to higher temperatures.

Application temperature +15˚C - +20˚C

Fields of applications :

Material moisture %13 ± 2

• Moisture resistant gluing of windows, doors and stairs Pressing time surface gluing 20-25 min

according to EN204/D3. Pressing time assembly bonding 8-15 min

• Surface bonding of decorative papers.

• High frequency bonding. pressure 0.1-1.0 N/mm²

• Stationary edge gluing with veneers, plastic laminates

and solid wood stripe. Prüfberichte

• Surface bonding of decorative high pressure laminates IFT INSTITUT ROSENHEIM GERMANY

in short-cycle press.

• Cabinet and assembly bonding with medium pressing Test Report No: 505 27229/3 DIN EN 204 D4

times and preheating devices.

• Board joint and block gluing of softwood, hardwoods Test Report No: 505 27229/3 R1

and chipboards

DIN EN 145257 (Watt-91) 10,0 N/mm²

Technical Data :

Base PVAc dispersion Technical Data Sheet

color White/ transparent cured

Skinning time 150 g/m² 8-12 min MSDS

Viscosity 13,000 mPa.s

Ph ca %5 ph Our user instructions, processing guidelines, product-

and performance data, and other technical statements

Applied quantity 80/140 g/m² (surface gluing) are only general directives; they describe only the

condition of our products (values, determination of

Applied quantity 160/200 g/m² (assembly bonding) values on the date of completion) and the

wood moisture %13 ± 2 performances do not represent a warranty.