Page 2 - CHEMETALL-8461-Silicon-Carbide-Catalog_R13_s

P. 2

Enhance wafer

and device yield

with the precision

chemical engineering

and expertise of

Chemetall.

At Chemetall, we focus on increasing process efficiency for

machining and finishing high-value materials. In the Silicon

Carbide Industry, we understand the challenges that arise

when crystals are grown by bulk and epitaxial processes, and

the variety of defects that can result. Our goal is to minimize

the impact of these defects and maximize your high-quality

wafer yields.

Our experts and innovators, as part of our global team,

are locally available, in-person, ready to meet your needs.

Along with individual process support, we manufacture

a full line of products for nearly every step of Silicon

Carbide wafer development.

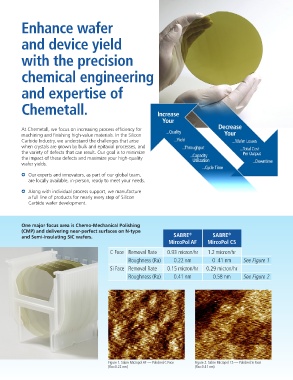

One major focus area is Chemo-Mechanical Polishing

(CMP) and delivering near-perfect surfaces on N-type

®

®

and Semi-Insulating SiC wafers. SABRE SABRE

MircoPol AF MircoPol CS

C Face Removal Rate 0.93 micron/hr 1.2 micron/hr

Roughness (Ra) 0.22 nm 0 .41 nm See Figure 1

Si Face Removal Rate 0.15 micron/hr 0.29 micron/hr

Roughness (Ra) 0.41 nm 0.58 nm See Figure 2

Figure 1. Sabre Micropol AF — Polished C Face Figure 2. Sabre Micropol CS — Polished Si Face

2 (Ra=0.22 nm) (Ra=0.41 nm)