Page 46 - 2017 UK Mini Catalogue - Easy Pen

P. 46

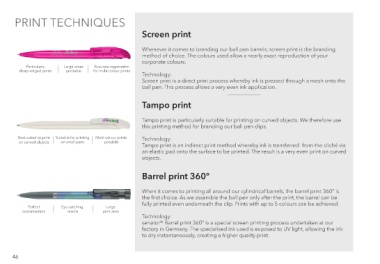

PRINT TECHNIQUES

Screen print

Whenever it comes to branding our ball pen barrels, screen print is the branding

method of choice. The colours used allow a nearly exact reproduction of your

corporate colours.

Particularly Large areas Accurate registration

sharp-edged prints printable for multi-colour prints

Technology:

Screen print is a direct print process whereby ink is pressed through a mesh onto the

ball pen. This process allows a very even ink application.

Tampo print

Tampo print is particularly suitable for printing on curved objects. We therefore use

this printing method for branding our ball pen clips.

Best suited to print Suitable for printing Multi-colour prints Technology:

on curved objects on small parts possible

Tampo print is an indirect print method whereby ink is transferred from the cliché via

an elastic pad onto the surface to be printed. The result is a very even print on curved

objects.

Barrel print 360°

When it comes to printing all around our cylindrical barrels, the barrel print 360° is

the first choice. As we assemble the ball pen only after the print, the barrel can be

fully printed even underneath the clip. Prints with up to 5 colours can be achieved.

Perfect Eye-catching Large

customisation results print area

Technology:

senator® Barrel print 360° is a special screen printing process undertaken at our

factory in Germany. The specialised ink used is exposed to UV light, allowing the ink

to dry instantaneously, creating a higher quality print.

46