Page 289 - Mold Bases & Plates 2020

P. 289

Technical Reference

296

American Standard Mold Base Features

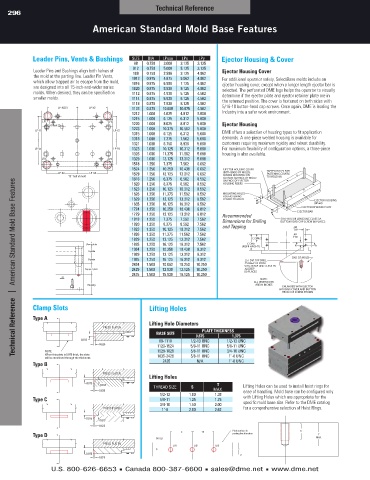

leader pins, vents & bushings sIze DIA lpxos lpx lpy ejector housing & Cover

88 0.750 3.000 3.125 3.125

812 0.750 5.000 5.125 3.125

Leader Pins and Bushings align both halves of 108 0.750 2.938 3.125 4.062 ejector housing Cover

W

the mold at the parting line. Leader Pin Vents, 1012 0.875 4.875 5.062 4.062

which allow trapped air to escape from the mold, 1016 0.875 6.938 7.125 4.062 For additional operator safety, SelectBase molds include an

are designed into all 15-inch-and-wider series 1020 0.875 8.938 9.125 4.062 ejector housing cover, except when a longer length ejector bar is

molds. When desired, they can be specified on 1112 0.875 4.938 5.125 4.562 selected. The perforated DME logo helps the operator to visually

smaller molds. 1114 0.875 5.938 6.125 4.562 determine if the ejector plate and ejector retainer plate are in

1118 0.875 7.938 8.125 4.562 the returned position. The cover is fastened on both sides with

z lp-XOs1 lp-X2 z 1123 0.875 10.688 10.875 4.562 5/16-18 button-head cap screws. Once again, DME is leading the

1212 1.000 4.625 4.812 5.000 industry into a safer work environment.

1215 1.000 6.125 6.312 5.000

lp1 lp2

OFFset (1) Offset (1) 1220 1.000 8.625 8.812 5.000 ejector housing

lp-y1 lp-y2 1223 1.000 10.375 10.562 5.000 DME offers a selection of housing types to fit application

1315 1.000 6.125 6.312 5.688

1318 1.000 7.375 7.562 5.688 demands. A one-piece welded housing is available for

1321 1.000 8.750 8.938 5.688 customers requiring maximum rigidity and robust durability.

lp-y3 lp-y4 1323 1.000 10.125 10.312 5.688 For maximum flexibility of configuration options, a three-piece

1326 1.000 11.375 11.562 5.688 housing is also available.

lp3 lp4 1329 1.000 13.125 13.312 5.688

1518 1.250 7.375 7.562 6.062

1524 1.250 10.250 10.438 6.062 EJECTOR HOUSING COVER TAPPED HOLES FOR

lp-X3 lp-X4 1529 1.250 13.125 13.312 6.062 (BOTH ENDS OF MOLD). FASTENING COVERS

”b” half of mold COVERS MOUNTED ON TO MOLD (8)

1616 1.250 6.375 6.562 6.562 OUTSIDE SURFACE OF MOLD

Technical Reference | American Standard Mold Base Features

ON ENDS OF EJECTOR

1620 1.250 8.375 8.562 6.562 HOUSING RISERS

1623 1.250 10.125 10.312 6.562

1626 1.250 11.375 11.562 6.562 MOUNTING HOLES

FOR FASTENING

1629 1.250 13.125 13.312 6.562 COVERS TO MOLD EJECTOR HOUSING

1635 1.250 16.125 16.312 6.562 (RISER)

EJECTOR RETAINER PLATE

1724 1.250 10.250 10.438 6.812 EJECTOR BAR

1729 1.250 13.125 13.312 6.812 Recommended

1818 1.250 7.375 7.562 7.562 Dimensions for Drilling 5/16-18 X 3/8 LONG UNC CLASS 3A

BUTTON HEAD CAP SCREW (8) PLACES

1820 1.250 8.375 8.562 7.562 and Tapping

1823 1.250 10.125 10.312 7.562 .44

TYP.

1826 1.250 11.375 11.562 7.562 .69

VIeW X-X C DIM/2 TYP.

("b" hAlF OF MOlD) 1829 1.250 13.125 13.312 7.562

C DIM

W clamp plate 1835 1.250 16.125 16.312 7.562 (RISER HEIGHT) A A

1924 1.250 10.250 10.438 8.312

A-plate

1929 1.250 13.125 13.312 8.312

y b-plate 1935 1.250 16.125 16.312 8.312 .257 DIA. TAP DRILL END OF MOLD

2424 1.500 10.062 10.250 10.250 .75 DEEP TO POINT

X .50 WIDe X .12 Deep 5/16-18 TAP UNC CLASS 2B

(4) plAces

centereD On eAch shOUlDer bUshInG, support plate 2429 1.500 12.938 13.125 10.250 .62 DEEP

InclUDInG the OFFset bUshInG -

In tOp OF rIsers On ejectOr hOUsInG (8) PLACES

FOr leADer pIn Vent slOts

2435 1.500 15.938 16.125 10.250

lpV-XOs lpV-X

(1) plAce (3) plAces NOTE:

ALL DIMENSIONS

housing ARE IN INCHES ENLARGED WITH EJECTOR

HOUSING COVER AND BUTTON

HEAD CAP SCREW SHOWN

sectIOn z-z

Clamp slots lifting holes

Type a

lifting hole diameters

press plAten

base size 0.875 plaTe ThiCkness 1.375

0.813 88-1118 1/2-13 Unc 1/2-13 Unc

0.625 1123-1524 5/8-11 Unc 5/8-11 Unc

nOte: 1529-1829 5/8-11 Unc 3/4-10 Unc

When this plate is 0.875 thick, the slots

will be machined through the thickness. 1835-2429 5/8-11 Unc 1"-8 Unc

Type b 2435 n/A 1"-8 Unc

press plAten

lifting holes

0.875 –X +X plate surface in

0.813 threAD sIze s T Lifting Holes can be used to install hoist rings for parting line direction

OFFset

0.625 MAX. ease of handling. Mold base can be configured only

1/2-13 1.00 1.38

lh2

lh3

Type C 5/8-11 1.25 1.75 with Lifting Holes which are appropriate for the

lh1

O

3/4-10 1.50 2.00 specific mold base size. Refer to the DME catalog

press plAten 1"-8 2.00 2.62 for a comprehensive selection of Hoist Rings. z

0.875

0.813

0.625

Type d –X +X plate surface in s t

parting line direction

OFFset MAX.

press plAten

lh1 lh2 lh3

O

0.875 z

0.625

U.S. 800-626-6653 ■ Canada 800-387-6600 ■ sales@dme.net ■ www.dme.net

s

t

MAX.