Page 2 - Parker - Fulflo PCC Filter Cartridge

P. 2

®

Fulflo PCC Filter Cartridge

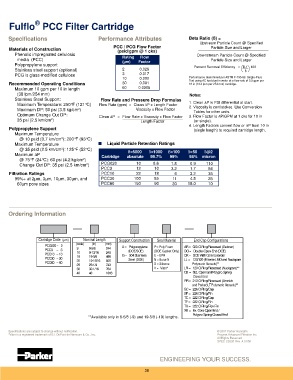

Specifications Performance Attributes Beta Ratio (ß) =

Upstream Particle Count @ Specified

PCC / PCG Flow Factor Particle Size and Larger

Materials of Construction (psid/gpm @ 1 cks)

Phenolic impregnated cellulosic Downstream Particle Count @ Specified

Rating Flow

media (PCC) (µm) Factor Particle Size and Larger

Polypropylene support Percent Removal Efficiency = ß-1 100

Stainless steel support (optional) 2 0.026 ß

PCG is glass-modified cellulose 3 0.017

10 0.002 Performance determined per ASTM F-795-88. Single-Pass

Test using AC test dust in water at a flow rate of 3.5 gpm per

Recommended Operating Conditions 30 0.001 10 in (13.2 lpm per 254 mm) cartridge.

Maximum 10 gpm per 10 in length 60 0.0005

(38 lpm/254 mm) Notes:

Stainless Steel Support: Flow Rate and Pressure Drop Formulas

Maximum Temperature: 250°F (121°C) Flow Rate (gpm) = Clean P x Length Factor 1. Clean P is PSI differential at start.

2. Viscosity is centistokes. Use Conversion

2

Maximum DP: 50 psi (3.5 kg/cm ) Viscosity x Flow Factor

Tables for other units.

Optimum Change Out DP: Clean P = Flow Rate x Viscosity x Flow Factor 3. Flow Factor is P/GPM at 1 cks for 10 in

2

35 psi (2.5 km/cm ) Length Factor (or single).

4. Length Factors convert flow or P from 10 in

Polypropylene Support (single length) to required cartridge length.

Maximum Temperature

2

@ 10 psid (0.7 km/cm ): 200°F (93°C)

Maximum Temperature

2

@ 35 psid (2.5 km/cm ): 125°F (52°C) ß=5000 ß=1000 ß=100 ß=50 ß@2

Maximum P Cartridge absolute 99.7% 99% 98% micron

@ 75°F (24°C): 60 psi (4.2 kg/cm )

2

Change Out DP: 35 psi (2.5 km/cm ) PCG020 10 8.6 1.8 0.9 110

2

PCC3 12 10 3.2 1.7 64

Filtration Ratings PCC10 22 18 6 3.2 35

99%+ at 2µm, 3µm, 10µm, 30µm, and PCC30 100 85 11 4.5 25

60µm pore sizes PCC60 150 90 30 15.0 10

Ordering Information

Cartridge Code (µm) Nominal Length Support Construction Seal Material End Cap Configurations

(code) (in) (mm)

PCG020 2 A = Polypropylene P = Poly Foam AR = 020 O-Ring/Recessed (Gelman)

PCC3 3 9 9-5/8 244 (DOE/SOE) (DOE Gasket Only) DO = Double-Open-End (DOE)

PCC10 10 10 9-13/16 249

19 19-5/8 498 G = 304 Stainless E = EPR DX = DOE With Core Extender

PCC30 30

20 19-15/16 506 Steel (DOE) N = Buna-N LL = 120/120 (Filterite LMO and Nuclepore

PCC60 60

29 29-1/4 743 S = Silicone Polymeric Vessels)**

30 30-1/16 764 V = Viton* LR = 120 O-Ring/Recessed (Nuclepore)**

40 40 1016 OB = Std. Open End/Polypro Spring

Closed End

PR = 213 O-Ring/Recessed (Ametek

and Parker)LT Polymeric Vessels)**

SC = 226 O-Ring/Cap

SF = 226 O-Ring/Fin

TC = 222 O-Ring/Cap

TF = 222 O-Ring/Fin

TX = 222 O-Ring/Flex Fin

XB = Ex. Core Open End /

Polypro Spring Closed End

**Available only in 9-5/8 (-9) and 19-5/8 (-19) lengths.

Specifications are subject to change without notification. © 2007 Parker Hannafin

*Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc. Process Advanced Filtration Inc.

All Rights Reserved

SPEC-C2020-Rev. A 01/08

ENGINEERING YOUR SUCCESS.

36