Page 28 - Parker - Check Valves

P. 28

Catalog HY15-3502/US Pilot Operated Check Valve

Technical Information Series D4A020

CV

General Description

Miniature Pilot to Open, Poppet Type Check Valve.

For additional information see Technical Tips on

Valves

Check

pages CV1-CV4.

SH

Features

• Hardened poppet for maximum durability

• Low leakage - less than 3 drops/min. (3)

Shuttle

Valves

LM • Sealed pilot

• Extremely compact construction - can be fitted directly

into most cylinders

• Cavity commonality with load control valves (2)

• Dual line blocks available

Controls

Load/Motor

FC

• All external parts zinc plated

(1)

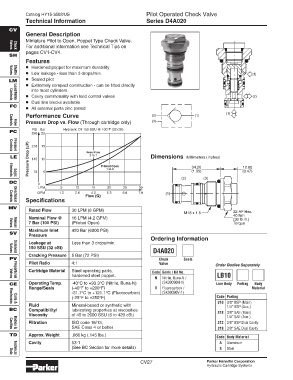

Performance Curve (2) (1)

Pressure Drop vs. Flow (Through cartridge only) (3)

Flow

Controls

PSI Bar Hydraulic Oil 150 SSU @ 100°F (32 cSt)

PC

290 20

P)

218 15

Pressure Drop ( Piloted Open 34.20 12.00

Controls

Pressure

2 to 1

LE 145 10 Free Flow Dimensions Millimeters (Inches)

1 to 2

5

73

Logic

(2) (1.35) (3) (0.47)

Elements

DC

0

LPM 5 10 15 20 25 30

0

GPM 1.3 2.6 4.0 5.3 6.6 7.9 (1)

Flow (Q)

Specifications

Directional

Controls

MV

Rated Flow 30 LPM (8 GPM)

M18 x 1.5 22 AF Hex.

40 Nm

Nominal Flow @ 16 LPM (4.2 GPM) (30 lb. ft.)

7 Bar (100 PSI) (Piloted Open) Torque

Manual

Valves

Maximum Inlet 420 Bar (6000 PSI)

SV

Pressure

Ordering Information

Leakage at Less than 3 drops/min.

150 SSU (32 cSt)

D4A020

Solenoid

Valves

Cracking Pressure 5 Bar (72 PSI)

PV Check Seals

Pilot Ratio 4:1 Valve Order Bodies Separately

Cartridge Material Steel operating parts, Code Seals / Kit No.

hardened steel poppet. LB10

N Nitrile, Buna-N /

Valves

Proportional

CE Operating Temp. -40°C to +93.3°C (Nitrile, Buna-N) (SK30090N-1) Line Body Porting Body

Range/Seals (-40°F to +200°F) V Fluorocarbon / Material

-31.7°C to +121.1°C (Fluorocarbon) (SK30090V-1)

(-25°F to +250°F) Code Porting

310 3/8″ BSP (Main)

Electronics

Coils &

Fluid Mineral-based or synthetic with 1/4″ BSP (Aux.)

BC Compatibility/ lubricating properties at viscosities

Viscosity of 45 to 2000 SSU (6 to 420 cSt) 318 3/8″ SAE (Main)

1/4″ SAE (Aux.)

Filtration ISO code 16/13, 312 3/8″ BSP Dual Cavity

SAE Class 4 or better 319 3/8″ SAE Dual Cavity

Cavities

Bodies &

TD Approx. Weight .066 kg (.145 lbs.)

Code Body Material

Cavity 53-1 A Aluminum

(See BC Section for more details) S Steel

Data

Technical

CV27 Parker Hannifin Corporation

Hydraulic Cartridge Systems