Page 1 - Parker - ParMax Filter Vessel

P. 1

ParMax Filter Vessel

™

For High-Flow Capacity

™

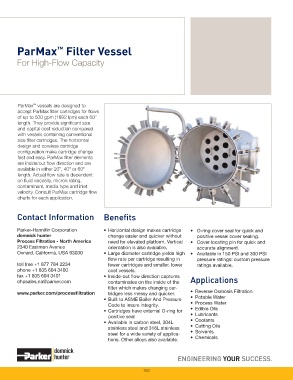

ParMax vessels are designed to

accept ParMax fi lter cartridges for fl ows

of up to 500 gpm (1892 lpm) each 60”

length. They provide signifi cant size

and capital cost reduction compared

with vessels containing conventional

size fi lter cartridges. The horizontal

design and coreless cartridge

confi guration make cartridge change

fast and easy. ParMax fi lter elements

are inside/out fl ow direction and are

available in either 20”, 40" or 60"

length. Actual fl ow rate is dependent

on fl uid viscosity, micron rating,

contaminant, media type and inlet

velocity. Consult ParMax cartridge fl ow

charts for each application.

Contact Information Benefi ts

Parker-Hannifi n Corporation • Horizontal design makes cartridge • O-ring cover seal for quick and

domnick hunter change easier and quicker without positive vessel cover sealing.

Process Filtration - North America need for elevated platform. Vertical • Cover locating pin for quick and

2340 Eastman Avenue orientation is also available. accurate alignment.

Oxnard, California, USA 93030 • Large diameter cartridge yields high • Available in 150 PSI and 300 PSI

fl ow rate per cartridge resulting in pressure ratings: custom pressure

toll free +1 877 784 2234 fewer cartridges and smaller, lower ratings available.

phone +1 805 604 3400 cost vessels.

fax +1 805 604 3401 • Inside-out fl ow direction captures Applications

dhpsales.na@parker.com contaminates on the inside of the

fi lter which makes changing car-

www.parker.com/processfi ltration tridges less messy and quicker. • Reverse Osmosis Filtration

• Potable Water

• Built to ASME Boiler And Pressure

• Process Water

Code to insure integrity.

• Edible Oils

• Cartridges have external O-ring for

• Lubricants

positive seal

• Coolants

• Available in carbon steel, 304L

• Cutting Oils

stainless steel and 316L stainless

• Solvents

steel for a wide variety of applica-

• Chemicals

tions. Other alloys also available.

153