Page 4 - Ingersoll Rand - ARO 5-Gallon Extrusion Packages and Rams

P. 4

4 5

Pump selection guide

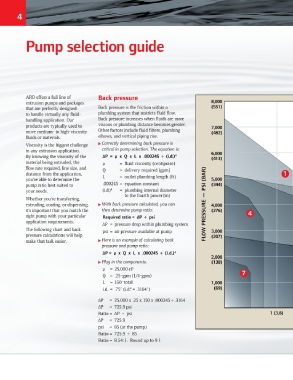

ARO offers a full line of Back pressure Need further

extrusion pumps and packages 8,000

that are perfectly designed Back pressure is the friction within a (551) assistance?

to handle virtually any fluid- plumbing system that restricts fluid flow. MODEL PUMP RATIO PAGE

handling application. Our Back pressure increases when fluids are more 1 NP665EC43RX-XX 650698-C43 65:1 8 You have a lot riding on the

products are typically used to viscous or plumbing distance becomes greater. 7,000 2 NP646EC43RX-XX 650692-C43-B 46:1 10 performance of your fluid-handling

move medium- to high-viscosity Other factors include fluid filters, plumbing (482) 3 NP844EC4DR8-XX 650891-C4D-C 44:1 12 system. So, it’s critical that the pump

fluids or materials. elbows, and vertical piping rise. and accessories you choose are not

Viscosity is the biggest challenge Correctly determining back pressure is 4 NP443XP43RX-XX 6712X-P43 43:1 14 only suitable for your application,

in any extrusion application. critical in pump selection. The equation is: 6,000 5 NP423EC43RX-XX 650492-C43-B 23:1 16 but also deliver peace-of-mind

By knowing the viscosity of the ΔP = μ x Q x L x .000245 ÷ (i.d.) 4 (413) 6 NP623EC43RX-XX 650691-C43-B 23:1 16 dependability and precision.

material being extruded, the μ = fluid viscosity (centipoise) 7 NP322XP43RX-XX NM2322X-11-P43 22:1 18 Whether you’re moving a small

flow rate required, line size, and Q = delivery required (gpm) amount of low-viscosity fluid a few

distance from the application, L = outlet plumbing length (ft) 1 feet or a large amount of high-

you’re able to determine the 5,000 viscosity material a longer distance,

pump ratio best suited to .000245 = equation constant (344) ARO has a pump and accessories to

4

your needs. (i.d.) = plumbing internal diameter meet your needs.

to the fourth power (in)

Whether you’re transferring, Specialty resins If you need additional assistance

extruding, coating, or dispensing, With back pressure calculated, you can FLOW PRESSURE — PSI (BAR) 4,000 Autobody sealers in selecting the right products

it’s important that you match the then determine pump ratio: (276) 4 2 300,000 cP for your specific application,

right pump with your particular Required ratio = ΔP ÷ psi feel free to contact ARO directly.

application requirements. 3 Greases We’ll get your questions

ΔP = pressure drop within plumbing system

The following chart and back psi = air pressure available at pump 3,000 Silicones answered and your product

pressure calculations will help (207) needs addressed quickly and

make that task easier. Here is an example of calculating back 200,000 cP efficiently.

pressure and pump ratio: Polysulfides (or greater) Contact us

ΔP = μ x Q x L x .000245 ÷ (i.d.) 4 5

2,000 50,000 cP

Plug in the components. (138) Lithographic inks (800) 495-0276

μ = 25,000 cP 6 fluids.ingersollrand.com

Q = .25-gpm (1/4-gpm) 7 Automotive epoxies

L = 150' total 1,000 20,000 cP

4

i.d. = .75" (i.d. = .3164") (69)

Acrylic caulks

ΔP = 25,000 x .25 x 150 x .000245 ÷ .3164

5,000 cP

ΔP = 725.9 psi

Ratio = ΔP ÷ psi 1 (3.8) 2 (7.6) 3 (11.4) 4 (15)

ΔP = 725.9 FLOW RATE — GPM (L/MIN)

psi = 85 (at the pump)

Ratio = 725.9 ÷ 85

Ratio = 8.54:1. Round up to 9:1

(800) 495-0276 • fluids.ingersollrand.com

Footer 5