Page 5 - Schmalz - Aluminum Crane Systems

P. 5

Kran_MH_Brosch_2014_EN_MH_Bro_EN.qxd 29.09.14 09:15 Seite 5

Aluminum Crane Systems from Schmalz

Overview of Highlights

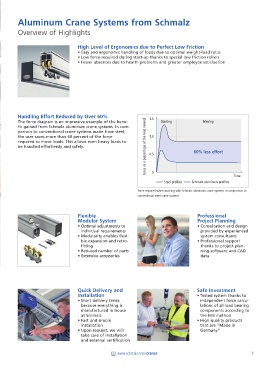

High Level of Ergonomics due to Perfect Low Friction

• Easy and ergonomic handling of loads due to optimal weight-load ratio

• Low force required during start-up thanks to special low friction rollers

• Fewer absences due to health problems and greater employee satisfaction

Handling Effort Reduced by Over 60% 1.5

The force diagram is an impressive example of the bene- Starting Moving

fit gained from Schmalz aluminum crane systems. In com-

parison to conventional crane systems made from steel,

the user saves more than 60 percent of the force 1.0

required to move loads. This allows even heavy loads to

be handled effortlessly and safely. Force as a percentage of the load moved 0.5 60% less effort

0

Time

Steel profiles Schmalz aluminum profiles

Force required when working with Schmalz aluminum crane systems in comparison to

conventional steel crane systems

Flexible Professional

Modular System Project Planning

• Optimal adjustments to • Consultation and design

individual requirements provided by experienced

• Modularity enables flexi- system consultants

ble expansion and retro- • Professional support

fitting thanks to project plan-

• Reduced number of parts ning software and CAD

• Extensive accessories data

Quick Delivery and Safe Investment

Installation • Tested system thanks to

• Short delivery times independent force calcu-

because everything is lations of all load bearing

manufactured in house components according to

at Schmalz the FEB method

• Fast and simple • High-quality products

instal lation that are “Made in

• Upon request, we will Germany”

take care of installation

and external certification

www.schmalz.com/cranes 5