Page 5 - Parker - Flow Control Valves

P. 5

Catalog HY15-3502/US

Technical Tips Flow Control Valves

CV

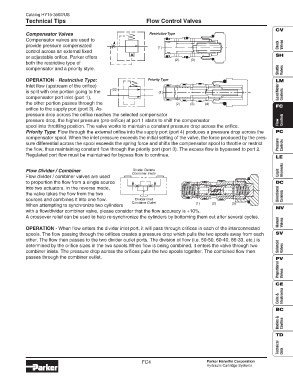

Compensator Valves Restrictive Type

Compensator valves are used to

provide pressure compensated Check Valves

(1)

control across an external fixed

SH

or adjustable orifice. Parker offers

(2) (3)

both the restrictive type of

Shuttle Valves

compensator and a priority style.

OPERATION - Restrictive Type: Priority Type LM

Inlet flow (upstream of the orifice)

is split with one portion going to the (1) Load/Motor Controls

compensator port inlet (port 1),

the other portion passes through the (2) (3) (4) FC

orifice to the supply port (port 3). As

pressure drop across the orifice reaches the selected compensator

pressure drop, the higher pressure (pre-orifice) at port 1 starts to shift the compensator Flow Controls

spool into throttling position. The valve works to maintain a constant pressure drop across the orifice.

Priority Type: Flow through the external orifice into the supply port (port 4) produces a pressure drop across the PC

compensator spool. When the inlet pressure exceeds the initial setting of the valve, the force produced by the pres-

sure differential across the spool exceeds the spring force and shifts the compensator spool to throttle or restrict Pressure Controls

the flow, thus maintaining constant flow through the priority port (port 3). The excess flow is bypassed to port 2.

Regulated port flow must be maintained for bypass flow to continue.

LE

Flow Divider / Combiner Divider Outlets Elements

Combiner Inlets Logic

Flow divider / combiner valves are used

to proportion the flow from a single source DC

into two actuators. In the reverse mode,

the valve takes the flow from the two Directional Controls

sources and combines it into one flow. Divider Inlet

Combiner Outlet (1) (2) (3)

When attempting to synchronize two cylinders

MV

with a flow/divider combiner valve, please consider that the flow accuracy is +10%.

A crossover relief can be used to help re-synchronize the cylinders by bottoming them out after several cycles.

Manual Valves

OPERATION - When flow enters the divider inlet port, it will pass through orifices in each of the interconnected

spools. The flow passing through the orifices creates a pressure drop which pulls the two spools away from each SV

other. The flow then passes to the two divider outlet ports. The division of flow (i.e. 50-50, 60-40, 66-33, etc.) is

determined by the orifice sizes in the two spools.When flow is being combined, it enters the valve through two Solenoid Valves

combiner inlets. The pressure drop across the orifices pulls the two spools together. The combined flow then

passes through the combiner outlet. PV

Proportional Valves

CE

Coils & Electronics

BC

Bodies & Cavities

TD

Technical Data

FC4 Parker Hannifin Corporation

Hydraulic Cartridge Systems