Page 2 - Parker - Fulflo MegaBond Nominal Filter Cartridges

P. 2

™

®

Fulfl o MegaBond Nominal Filter Cartridges

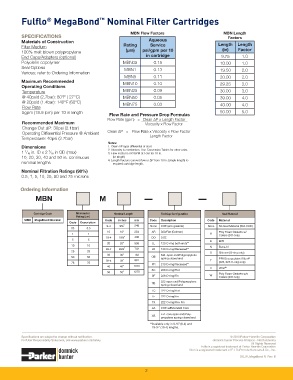

MBN Flow Factors MBN Length

SPECIFICATIONS Factors

Materials of Construction Aqueous

Filter Medium Rating Service Length Length

100% melt blown polypropylene (µm) psi/gpm per 10 (in) Factor

End Caps/Adapters (optional) in cartridge 9.75 1.0

Polyolefi n copolymer MBN05 0.15 10.00 1.0

Seal Options MBN1 0.13 19.50 2.0

Various; refer to Ordering Information

MBN5 0.11 20.00 2.0

Maximum Recommended MBN10 0.10 29.25 3.0

Operating Conditions

Temperature MBN25 0.09 30.00 3.0

@ 40psid (2.7bar): 80°F ( 27°C) MBN50 0.05 39.00 4.0

@ 20psid (1.4bar): 140°F (60°C) MBN75 0.03 40.00 4.0

Flow Rate

5gpm (18.9 lpm) per 10 in length 50.00 5.0

Flow Rate and Pressure Drop Formulas

Flow Rate (gpm) = Clean ΔP x Length Factor

Recommended Maximum Viscosity x Flow Factor

Change Out P: 30psi (2.1bar)

Operating Differential Pressure @ Ambient Clean ΔP = Flow Rate x Viscosity x Flow Factor

Length Factor

Temperature: 40psi (2.7bar)

Notes:

Dimensions 1. Clean ΔP ispsi differential at start.

2. Viscosity is centistokes. Use Conversion Tables for other units.

7

1 ⁄ 16 in. ID x 2 ⁄ 16 in OD (max) 3. Flow Factor is ΔP/GPM at 1cks for 10 in.

1

10, 20, 30, 40 and 50 in. continuous (or single).

4. Length Factors convert fl ow or ΔP from 10 in. (single length) to

nominal lengths required cartridge length.

Nominal Filtration Ratings (90%)

0.5, 1, 5, 10, 25, 50 and 75 microns

Ordering Information

MBN M — —

Cartridge Code Micrometer Nominal Length End Cap Confi guration Seal Material

Rating (µm)

MBN MegaBond Nominal Code Inches mm Code Description Code Material

Code Description

9-4 9¾ " 248 None DOE (w/o gaskets) None No Seal Material (Std. DOE)

05 0.5

10 10" 254 AR 020/Flat (Gelman) Poly Foam Gaskets w/

1 1 A Collars (DO only)

19-4 19½ " 495 DO DOE

5 5 E EPR

20 20" 508 LL 120 O-ring both ends**

10 10 N Buna-N

29-4 29¼ " 743 LR 120 O-ring/Recessed**

25 25 S Silicone (O-ring only)

30 30" 762 Std. open end/Polypropylene

50 50 OB spring closed end PFA Encapsulated Viton ®

39-4 39 " 991 T

75 75 PR 213 O-ring/Recessed** (222, 226 O-ring only)

40 40 " 1016

V Viton ®

SC 226 O-ring/Flat

50 50 " 1270 Poly Foam Gaskets w/o

SF 226 O-ring/Fin W Collars (DO only)

222 open end/Polypropylene

TB

spring closed end

TC 222 O-ring/Flat

TF 222 O-ring/Fin

TX 222 O-ring/Flex Fin

XA DOE w/Extended Core

Ext. core open end/Poly-

XB

propylene spring closed end

** Available only in 9-¾” (9-4) and

19-½” (19-4) lengths.

Specifi cations are subject to change without notifi cation. © 2010 Parker-Hannifi n Corporation

For User Responsibility Statement, see www.parker.com/safety domnick hunter Process Filtration - North America

All Rights Reserved

Fulfl o is a registered trademark of Parker-Hannifi n Corporation

Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

DS_IP_MegaBond N Rev. B

2