Page 2 - Parker - Shuttle Valves

P. 2

Catalog HY15-3502/US

Technical Tips Shuttle Valves

CV

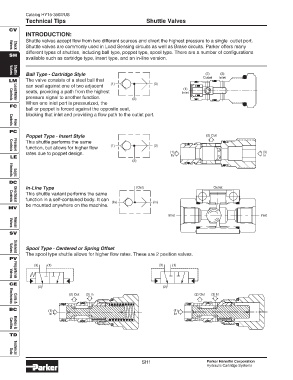

INTRODUCTION:

Shuttle valves accept flow from two different sources and divert the highest pressure to a single outlet port.

Shuttle valves are commonly used in Load Sensing circuits as well as Brake circuits. Parker offers many

Valves

Check

different types of shuttles, including ball type, poppet type, spool type. There are a number of configurations

SH

available such as cartridge type, insert type, and an in-line version.

Ball Type - Cartridge Style (2) (3)

Valves

Shuttle

Outlet Inlet

LM The valve consists of a steel ball that

(1) (3)

can seal against one of two adjacent

(1)

seats, providing a path from the highest Inlet

pressure signal to another function. (2)

Load/Motor

Controls

When one inlet port is pressurized, the

FC

ball or poppet is forced against the opposite seat,

blocking that inlet and providing a flow path to the outlet port.

Controls

Flow

PC

Poppet Type - Insert Style (2) Out

This shuttle performs the same

(1) (3)

function, but allows for higher flow

Pressure

Controls

rates due to poppet design. (1) (3)

In

In

LE

(2)

Elements

Logic

DC

In-Line Type (Out) Outlet

This shuttle variant performs the same

function in a self-contained body. It can

(In) (In)

Directional

Controls

be mounted anywhere on the machine.

MV

Inlet Inlet

Manual

Valves

SV

Spool Type - Centered or Spring Offset

The spool type shuttle allows for higher flow rates. These are 2 position valves.

Solenoid

Valves

PV

(3) (1) (3) (1)

Valves

Proportional

CE

(2) (2)

(2) Out (3) In (2) Out (3) In

Coils &

Electronics

BC (1) (1)

In In

Bodies &

Cavities

TD

Data

Technical

SH1 Parker Hannifin Corporation

Hydraulic Cartridge Systems