Page 4 - Parker - Process filtration vessels

P. 4

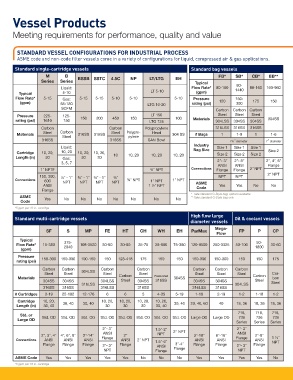

Vessel Products

Meeting requirements for performance, quality and value

STANDARD VESSEL CONFIGURATIONS FOR INDUSTRIAL PROCESS

ASME code and non-code fi lter vessels come in a variety of confi gurations for liquid, compressed air & gas applications.

Standard single-cartridge vessels Standard bag vessels

M B FB* SB* CB* EB**

Series Series BSSB SSTC 4.5C NP LT/LTG EH

Typical

80-

Liquid: Flow Rate* 80-160 1440 80-160 160-960

Typical 5-10 LT 5-10 (gpm)

Flow Rate* 5-15 Gas: 5-15 5-15 5-10 5-10 5-10 Pressure 150-

(gpm) 65-180 LTG 10-20 rating (psi) 150 300 175 150

SCFM Carbon Carbon Carbon

Pressure 225- 125- LT 150 Steel Steel Steel

rating (psi) 1610 150 150 200 450 150 LTG 125 100 Materials 304LSS 304SS 304SS 304SS

Carbon Carbon Polypropylene 316LSS 316SS 316SS

Steel Carbon Steel Polypro- Head

Materials 316SS 316SS 304 SS # Bags 1 1-9 1 1-6

Steel pylene

316SS 316SS SAN Bowl

7½˝ diameter 7˝ diameter

Industry

Liquid: Size 1 Size 1 Size 1

Cartridge 10, 20, 10, 20 10, 20, 10, 20, Bag Size Size 2 Size 2 Size 2 Size 2

Length (in) 30 Gas: 30 30 10 10, 20 10, 20 10, 20

3, 5, 7 2˝- 3˝ 2˝- 8˝ 2˝, 4˝, 6˝

ANSI ANSI Flange

1˝ NPTF ¾˝ NPT Connections Flange Flange 2˝ NPT

2˝ NPT

150, 300, ¼˝ - 1˝ ¾˝ - 1˝ ¾˝ - 1˝ ¾˝ NPT NPT

Connections 600 NPT NPT NPT NPT ¾˝ NPT 1˝ NPT 1˝ NPT

ANSI 1 ½˝ NPT ASME Yes Yes No No

Flange Code

* Take standard C-Style bag, options available

ASME ** Take standard G-Style bag only

Code Yes No No No No No No No

*5 gpm per 10 in. cartridge

High fl ow large

Standard multi-cartridge vessels Oil & coolant vessels

diameter vessels

Mega-

SF S MP FE HT CH WH EH ParMax FP P CP

Flow

Typical

Flow Rate* 15-380 375- 108-3520 30-90 30-90 25-75 28-980 75-380 120-9500 250-3325 50-100 50- 30-60

(gpm) 2040 1800

Pressure

150-300 150-300 100-150 150 123-418 175 150 150 150-300 150-300 150 150 175

rating (psi)

Carbon Carbon 304LSS Carbon Carbon Carbon Carbon Carbon

Steel Steel Steel Carbon Steel Passivated Steel Steel Steel Carbon Car-

Materials 304SS bon

304SS 304SS 304LSS Steel 304SS 316SS 304SS 304SS Steel

316LSS 304LSS Steel

316SS 316SS 316LSS 316SS 316LSS 316SS

# Cartridges 3-19 25-102 12-176 6 6 5 4-35 5-19 1-19 2-19 1-2 1-18 1-2

Cartridge 10, 20, 10, 20, 10, 20, 10, 20, 10, 20,

Length (in) 30, 40 30, 40 30, 40 30 30 30 30, 40 30, 40 20, 40, 60 40 18, 36 18, 36 18, 36

718, 718, 718,

Std. or

Std. OD Std. OD Std. OD Std. OD Std. OD Std. OD Std. OD Std. OD Large OD Large OD 736 736 736

Large OD

Series Series Series

2˝- 3˝ 1.5˝-2˝ 2˝- 3˝

ANSI NPT 2” NPT ANSI

2˝, 3˝, 4˝ 4˝, 6˝, 8˝ 3˝-14˝ 2˝ 3˝-18˝ 6˝-16˝ 2˝-8˝ 1 ½˝

Connections ANSI ANSI ANSI Flange ANSI 2˝ NPT 1.5˝-6˝ ANSI ANSI Flange ANSI NPT

Flange Flange Flange 2˝- 3˝ Flange ANSI 3˝-4˝ Flange Flange 2˝- 3˝ Flange

NPT Flange Flange NPT

ASME Code Yes Yes Yes Yes Yes No No No Yes Yes Yes Yes No

*5 gpm per 10 in. cartridge