Page 3 - Parker - Oil and Gas Production

P. 3

Adding value to your business

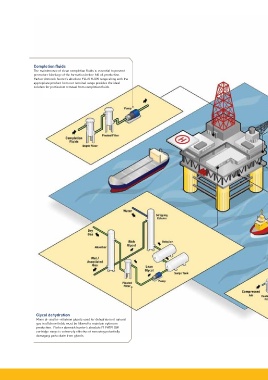

From completion to production

Completion fluids

The maintenance of clean completion fluids is essential to prevent

premature blockage of the formation before full oil production.

Supported by high quality products, an international team of specialists and a Parker domnick hunter’s absolute PLEATFLOW range along with the

appropriate product from our nominal range provides the ideal

commitment to providing first-class technical support, Parker domnick hunter solution for particulate removal from completion fluids.

Process Filtration understands the specific needs of the offshore industry.

Our dedicated product range delivers quality, consistency and cost-effectiveness

throughout your process, wherever and whenever you need it. Water injection

Particulate such as sand, shale and algae within seawater

can cause blockage of the formation when injected, which

can severely damage productivity. Parker domnick hunter’s

PLEATFLOW pleated cartridge range is proven to provide

Trusted solutions to meet Global support with a superior clarity in water injection systems. Our nominal

your needs local perspective range provides ideal prefiltration where required.

With rising costs of recovery through Wherever you are in the world and

deeper and deeper exploration and whatever the requirements of your

increasing safety, quality and process, Parker domnick hunter’s

environmental requirements, you need dedicated support team is there to

a filtration supplier that can ensure help you get the most out of your

economy, reliability and reproducible filtration systems.

quality throughout your process.

We have a presence in all of the major

As leaders in drilling fluid filtration, oil producing regions offering you

Parker domnick hunter offers a local customer support and technical

dedicated product range to meet all back-up for all of your offshore filtration

these requirements from completion applications.

fluids to produced water.

Produced water

Produced water contains oil in various proportions which

Delivering on our promises must be removed prior to disposal back into the sea to

comply with environmental regulations. Parker domnick

Parker domnick hunter understands hunter’s SORBFLOW oil absorbent elements can ensure

that quick turnaround on consumables produced water meets environmental limits prior to disposal

through effective removal of trace oil after bulk separation.

for fluid applications is a critical aspect

of successful operation in offshore oil

recovery.

Our business is structured to provide

high levels of stock availability and

short lead times so we can satisfy the

delivery requirements of the offshore

industry, ensuring the right product is

delivered on time, every time.

Nitrogen generation

Glycol dehydration

Mono di- and tri- ethylene glycols used for dehydration of natural Adequate purging is essential to produce inert

systems that are free from combustible gas.

gas in offshore fields must be filtered to maintain optimum Parker domnick hunter’s range of nitrogen

production. Parker domnick hunter’s absolute PLEATFLOW generators provides purge gases on demand

cartridge range is extremely effective at removing potentially without the need for high pressure storage

damaging particulate from glycols.

bottles and their associated disadvantages.