Page 2 - Parker - Fulflo CB Filter Vessels

P. 2

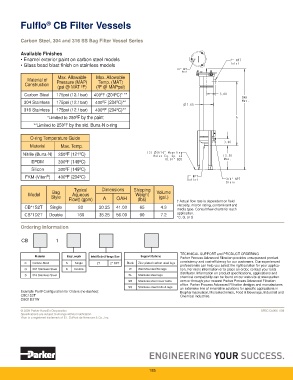

Fulfl o CB Filter Vessels

®

Carbon Steel, 304 and 316 SS Bag Filter Vessel Series

Available Finishes

• Enamel exterior paint on carbon steel models

• Glass bead blast fi nish on stainless models

Max. Allowable Max. Allowable

Material of

Construction Pressure (MAP) Temp. (MAT)

(psi @ MAT ºF) (ºF @ MAPpsi)

Carbon Steel 175psi (12.1bar) 400ºF (204ºC)* **

304 Stainless 175psi (12.1bar) 400ºF (204ºC)**

316 Stainless 175psi (12.1bar) 400ºF (204ºC)**

*Limited to 250ºF by the paint

**Limited to 250ºF by the std. Buna-N o-ring

O-ring Temperature Guide

Material Max. Temp.

Nitrile (Buna-N) 250ºF (121ºC)

EPDM 300ºF (149ºC)

Silicon 300ºF (149ºC)

®

FKM (Viton ) 400ºF (204ºC)

Typical Dimensions Shipping

Bag Volume

Model Aqueous Weight

Style (gal.)

Flow† (gpm) A OAH (lbs) † Actual fl ow rate is dependent on fl uid

CB*1S2T Single 80 20.25 41.00 65 4.3 viscosity, micron rating, contaminant and

media type. Consult fl ow charts for each

CB*1D2T Double 160 35.25 56.00 90 7.2 application.

*C, G, or S

Ordering Information

CB 1

TECHNICAL SUPPORT and PRODUCT ORDERING

Material Bag Length Support Options

Inlet/Outlet Flange Size Parker Process Advanced Filtration provides unsurpassed product

consistency and cost-effi ciency for our customers. Our experienced

C Carbon Steel S Single 2T 2” NPT Blank Zinc plated carbon steel legs

professionals can help you select the right solution for your applica-

G 304 Stainless Steel D Double W Wall Mounted/No legs tion. For more information or to place an order, contact your local

distributor. Information on product specifi cations, applications and

S 316 Stainless Steel SL Stainless steel legs

chemical compatibility can be found on our web site at www.parker.

SB Stainless steel cover bolts com or through your nearest Parker Process Advanced Filtration

offi ce. Parker Process Advanced Filtration designs and manufactures

SS Stainless steel bolts & legs an extensive line of innovative solutions for specifi c applications in

Example Part# Confi guration for Orders (no dashes): Biopharmaceutical, Microelectronics, Food & Beverage, Industrial and

CBC1S2T Chemical industries.

CBG1D2TW

© 2009 Parker Hannifi n Corporation SPEC C5006 7/09

Specifi cations are subject to change without notifi cation.

Viton is a registered trademark of E.I. DuPont de Nemours & Co., Inc.

155