Page 37 - Parker Catalog 4400 - Hose, Fittings and Equipment

P. 37

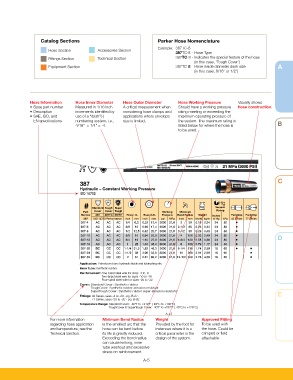

Catalog Sections Parker Hose Nomenclature

Example: 387TC-8

Hose Section Accessories Section

387TC-8 - Hose Type

Catalog 4400 US GlobalCore: 3000 PSI Hydraulic Hose: 387

Fittings Section Technical Section 387TC-8 - Indicates the special feature of the hose

(in this case, ‘Tough Cover’)

Equipment Section 387TC-8 - Hose inside diameter dash size A A

HYDRAULIC 387 (in this case, 8/16" or 1/2")

Markets Parker’s GlobalCore 387 hose provides 3,000 psi (21 MPa) constant working

pressure in all sizes. Available in a variety of cover options so you can match A A

the right cover to your application, 387 hose offers you the choice of Standard,

ToughCover and SuperTough Cover. Designed, built and tested to the ISO

Hose Information Hose Inner Diameter Hose Outer Diameter Hose Working Pressure Visually shows

18752 performance specifications. Parker’s 387 hose is unmatched in today’s

• Base part number Measured in 1/16 inch A critical measurement when Should have a working pressure hose construction.

marketplace.

• Description increments identified by considering hose clamps and rating meeting or exceeding the

• ½ ISO 18752 minimum bend radius

• SAE, ISO, and use of a “dash”(-) applications where envelope maximum operating pressure of

• Low force to flex for ease of installation

EN specifications numbering system. i.e., size is limited. the system. The maximum rating is

• 3,000 psi constant working pressure in all sizes

4/16" = 1/4" = -4. listed below for where the hose is B

• Exceeds ISO 18752 performance specification (AC, BC and CC)

to be used.

• Synthetic rubber inner tube provides a wider range of fluid compatibility B

• TC cover provides 80 times and ST cover 450 times abrasion resistance when

compared to standard covers

Performance

C

387 C

Hydraulic – Constant Working Pressure

ISO 18752

Hg

Standard Tough Super Vacuum

Part Cover Cover Tough Working Minimum Rating

Number 387 387TC 387ST Hose I.D. Hose O.D. Pressure Bend Radius Weight inches Parkrimp Parkrimp

387 ISO 18752 Performance inch mm inch mm psi MPa inch mm lbs/ft kg/m of Hg kPa 43 Series 77 Series D

387-4 AC AC AC 1/4 6,3 0.53 13,4 3000 21,0 2 50 0.16 0,24 24 80 •

387-6 AC AC AC 3/8 10 0.69 17,4 3000 21,0 2-1/2 65 0.23 0,34 24 80 •

387-8 AC AC AC 1/2 12,5 0.82 20,7 3000 21,0 3-1/2 90 0.29 0,43 24 80 •

387-10 AC AC AC 5/8 16 0.94 23,9 3000 21,0 4 100 0.33 0,49 24 80 • D

387-12 AC AC AC 3/4 19 1.10 27,8 3000 21,0 4-3/4 120 0.58 0,86 24 80 •

387-16 AC AC AC 1 25 1.40 35,4 3000 21,0 6 150 0.79 1,17 24 80 •

387-20 BC CC CC 1-1/4 31,5 1.82 46,3 3000 21,0 8-1/4 210 1.74 2,59 18 60 • •

387-24 BC CC CC 1-1/2 38 2.08 52,8 3000 21,0 10 250 2.01 2,99 18 60 •

387-32 BC CC CC 2 51 2.61 66,2 3000 21,0 12-1/2 320 2.75 4,09 18 60 •

Application: Petroleum base hydraulic fluids and lubricating oils. E

Inner Tube: Synthetic rubber.

Reinforcement: One-braid steel wire for sizes -4 to -8

Two-braid steel wire for sizes -10 to -16

Four-spiral steel wire for sizes -20 to -32

Cover: Standard Cover: Synthetic rubber

ToughCover: Synthetic rubber abrasion resistant

SuperTough Cover: Synthetic rubber super abrasion resistant

Fittings: 43 Series, sizes -4 to -20 - pg. B-27. E

77 Series, sizes -20 to -32 - pg. B-92.

Temperature Range: Standard Cover: -40°F to +212°F (-40°C to +100°C)

ToughCover & SuperTough Cover: -40°F to +257°F (-40°C to +125°C)

A-13

For more information Minimum Bend Radius Weight Approved Fitting

regarding hose application Is the smallest arc that the Provided by the foot for To be used with

and temperature, see the hose can be bent before instances where it is a the hose. Could be

Technical Section. its life is greatly reduced. critical parameter in the crimped or field

Exceeding the bend radius design of the system. attachable.

can cause kinking, inner

tube washout and excessive

stress on reinforcement.

A-5