Page 410 - Parker Catalog 4400 - Hose, Fittings and Equipment

P. 410

Catalog 4400 US Technical

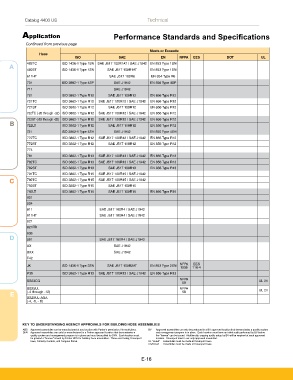

Application Performance Standards and Specifications

Continued from previous page

Meets or Exceeds:

Hose

ISO SAE EN NFPA EES DOT UL

A A 482TC ISO 1436-1 Type 1SN SAE J517 100R1AT / SAE J1942 EN 853 Type 1SN

482ST ISO 1436-1 Type 1SN SAE J517 100R1AT EN 853 Type 1SN

611HT SAE J517 100R6 EN 854 Type R6

701 ISO 3862-1 Type 4SP SAE J1942 EN 856 Type 4SP

711 SAE J1942

721 ISO 3862-1 Type R12 SAE J517 100R12 EN 856 Type R12

721TC ISO 3862-1 Type R12 SAE J517 100R12 / SAE J1942 EN 856 Type R12

721ST ISO 3862-1 Type R12 SAE J517 100R12 EN 856 Type R12

722TC (-20 through -32) ISO 3862-1 Type R12 SAE J517 100R12 / SAE J1942 EN 856 Type R12

722ST (-20 through -32) ISO 3862-1 Type R12 SAE J517 100R12 / SAE J1942 EN 856 Type R12

B 722LT ISO 3862-1 Type R12 SAE J517 100R12 EN 856 Type R12

731 ISO 3862-1 Type 4SH SAE J1942 EN 856 Type 4SH

772TC ISO 3862-1 Type R12 SAE J517 100R12 / SAE J1942 EN 856 Type R12

772ST ISO 3862-1 Type R12 SAE J517 100R12 EN 856 Type R12

774

781 ISO 3862-1 Type R13 SAE J517 100R13 / SAE J1942 EN 856 Type R13

782TC ISO 3862-1 Type R13 SAE J517 100R13 / SAE J1942 EN 856 Type R13

782ST ISO 3862-1 Type R13 SAE J517 100R13 EN 856 Type R13

791TC ISO 3862-1 Type R15 SAE J517 100R15 / SAE J1942

C 792TC ISO 3862-1 Type R15 SAE J517 100R15 / SAE J1942

792ST ISO 3862-1 Type R15 SAE J517 100R15

792LT ISO 3862-1 Type R15 SAE J517 100R15 EN 856 Type R15

801

804

811 SAE J517 100R4 / SAE J1942

811HT SAE J517 100R4 / SAE J1942

821

821FR

836

D 881 SAE J517 100R4 / SAE J1942

AX SAE J1942

BXX SAE J1942

F42

NFPA EES

JK ISO 1436-1 Type 2SN SAE J517 100R2AT EN 853 Type 2SN

1936 116-4

P35 ISO 3862-1 Type R13 SAE J517 100R13 / SAE J1942 EN 856 Type R13

SS23CG NFPA UL 21

58

SS25UL NFPA UL 21

E (-4 through -12) 58

SS25UL-AGA

(-4, -6, - 8)

KEY TO UNDERSTANDING AGENCY APPROVALS FOR BUILDING HOSE ASSEMBLIES

ABS Approved assemblies can be manufactured at any location with Parker’s permission. No restrictions. BV Approved assemblies can only be produced in a BV approved location that demonstrates a quality system

DNV Approved assemblies can only be manufactured in a Parker approved location that demonstrates a and management program is in place. Each location must have an initial audit performed by BV before

quality system and management program is in place and must be audited by DNV. Each location must the “license” can be issued. Additionally, ongoing audits setup by BV will be required at each approved

be granted a “license” issued by Parker HPD for building hose assemblies. Three exist today; Davenport location. Davenport Iowa is our only approved assembler.

Iowa, Grimsby Canada, and Yangsan Korea. UL “Listed” Assemblies must be made at Davenport Iowa

CSA/CGA Assemblies must be made at Davenport Iowa

E-16