Page 1 - Colder Products Company - DrumQuik PUR Dispensing System for Professional High Purity Chemical Management

P. 1

DrumQuik PUR

®

Dispensing System for Professional,

High Purity Chemical Management

DrumQuik PUR is an easy-to-use product for extracting high purity chemicals from rigid

®

containers (jerry cans, drums and IBCs) using common pumps within a closed-system design.

The integrated flare outlet fitting allows easy connections to chemically resistant tubing

such as PFA or FEP. The system minimizes chemical exposure and promotes employee and

environmental safety. DrumQuik PUR is ideally suited to cost-sensitive one-way/single-use

applications and can be disposed of, recycled along with the container or reused with a new

container. DrumQuik PUR products are manufactured in a cleanroom and double bagged to

maintain purity until ready for use.

FEATURES BENEFiTS

Quick connect/disconnect Allows faster container change-outs

All plastic construction No metallic corrosion/contamination

Applications:

Automatic shutoff valve Stops flow when disconnected

• Acids, caustics and

Cleanroom manufactured Assures high level of purity

solvent delivery

Disposable drum insert Minimizes chemical exposure & contamination

• Pharmaceutical chemical

Specifications handling

Pressure: • Semiconductor wet

Uncoupled: Vacuum to 45 psig (3.1 bar) process

Coupled: Vacuum to 22 psig (1.5 bar)

• Flat panel production

Temperature:

Drum insert: -20° to 120°F (-29° to 49°C) • Photovoltaic cell

Coupler: 0° to 120°F (-18° to 49°C)

manufacturing

Materials:

Drum insert & dip-tube: • Laboratory chemical

Virgin polyethylene (HDPE) handling

Shipping plug:

Virgin polyethylene (HDPE) DrumQuik PUR

®

Coupler: Virgin PVDF Flow Performance

Spring (coupler only):

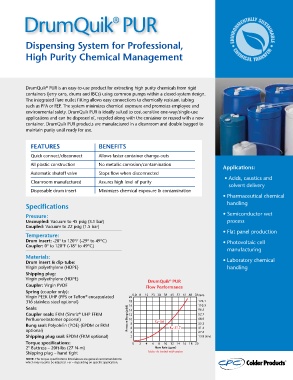

Virgin PEEK UHP (PPS or Teflon encapsulated 20 0.0 8 15 23 30 38 45 53 61 68 76 (lpm)

®

316 stainless steel optional) 18 124.1

Seals: 16 110.3

96.5

14

®

Coupler seals: FKM (Simriz UHP FFKM 12 82.7

Perfluoroelastomer optional) Pressure Drop (psid) 10 C v ~3.6 68.9

Bung seal: Polyolefin (POE) (EPDM or FKM 8 K v ~51.7 55.2

41.4

6

optional) 4 27.6

Shipping plug seal: EPDM (FKM optional) 2 13.8 (kPa)

Torque specifications: 0 2 4 6 8 10 12 14 16 18 20

2" Buttress – 20ft-lbs (27 N-m) Flow Rate (gpm)

Shipping plug – hand tight Note: As tested with water.

NOTE: The torque specifications listed above are general recommendations

which may need to be adjusted + or – depending on specific application.